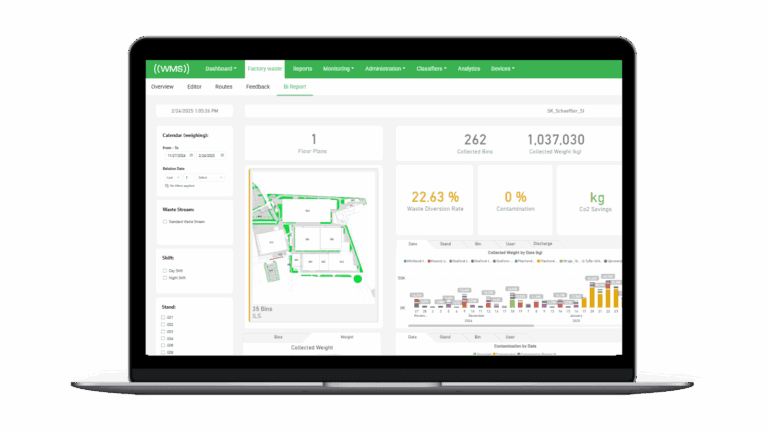

Operational efficiency and actionable analytics at your floorplan

Optimising resources

required for collection

Improving KPIs

like Waste Diversion Rate

Waste data

for sustainability reporting

Industry Waste Management for Factories & Facilities

In today’s industrial world, effective waste management isn’t just a goal. It’s a pressing necessity.

However, businesses encounter significant roadblocks on the path to achieving operational efficiency. Overflowing bins often go uncollected. This raises costs, causes missed pickups, and delays production. Also, unnecessary collection routes waste time and resources when bins are only half-full or empty.

But the challenges don’t stop there. Factories face pressure to comply with sustainability and ESG standards. They are struggling to gather accurate waste data. The amount of waste and its sources in the facility is often unknown.

Additionally, waste contamination complicates reporting and recycling. It hinders efforts to meet sustainability targets, such as improving the Waste Diversion Rate.

Problems we solve

- Delayed collection of overflowing bins disrupts your optimized logistics flow

- Unnecessary collection of half-empty bins disrupts your logistics line workforce

- Unnecessary routes are wasting your resources and increasing danger to safety

- Lack of data about the volume of the waste produced at each logistic step

- Contamination tracking in order to increase your sustainability goals

About our solution

Sensoneo’s smart waste solution brings order and transparency to waste collection at all types of facilities, including factories, hospitals, airports, and malls.

Our solution delivers two major benefits: actionable analytics and operational efficiency.

Key functionalities and benefits of our solution

Fullness notification

Smart sensors and monitors feed Sensoneo’s Waste Management System (WMS) with live measurements on bin fullness several times a day.

Smart Button allows assigned personnel to indicate that the bin is full. Upon pressing, it sends notifications to the Waste Management System.

Both Button and Sensor can be placed on bins, dumpsters and containers of various types and sizes and send notification from both indoor and outdoor locations. Smart Button is a simple and cost-efficient tool for hand-operated fullness notification. Smart Sensor is a reliable and effortless tool for automatic fullness notification.

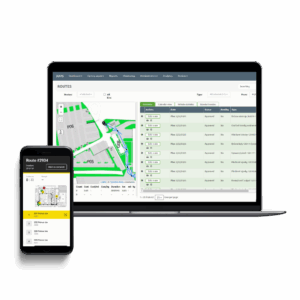

Waste Management System (WMS)

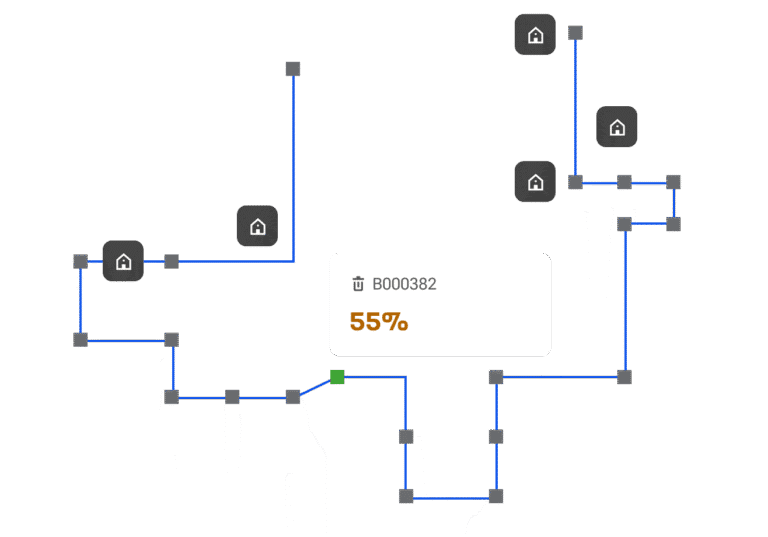

The Factory Waste Management Operator immediately sees all the full bins in Dashboard and Route Planning Engine automatically recalculates the routes to accommodate the new full bin. Both Dashboard and Route Planning Engine are part of Waste Management System (WMS), a powerful, cloud-based platform designed by Sensoneo.

The waste management software platform offers comprehensive control over waste collection operations through remote management. It efficiently adapts to diverse rules and variables, enabling the accommodation of various scenarios. You can create a detailed database of all the bins including waste types, capacities, bin locations, and bin pickup points.

Dashboard consolidates all the data from Smart Buttons, Smart Sensors and Mobile Collection App. By recalculating routes in real-time, particularly to address “full bin” notifications, the solution optimizes collection efficiency and responsiveness.

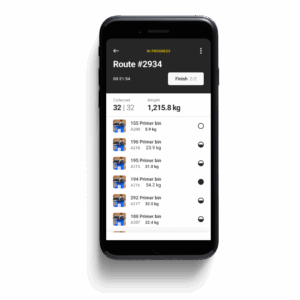

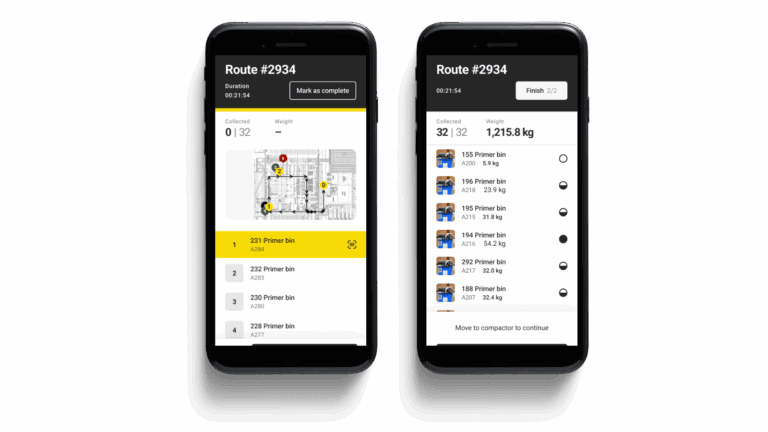

Mobile Collection App

Mobile Collection App revolutionizes waste management on floorplans of factories and facilities by streamlining essential tasks. We designed the Dashboard in Waste Management System (WMS) for Operators and Collection App for Drivers and Collectors.

Collection App helps drivers navigate the premises and identify bins for collection and transportation. It simplifies waste collection through a convenient To-do List, while Floorplan Navigation and QR code-based Bin/Stand Identification enhances operational efficiency.

The app further ensures service verification and enables prompt contamination feedback, promoting effective waste management practices and accountability. Collection App sends all the data to the Sensoneo Platform and Operator has remote control.

Data insights for optimisation

Our data reports offer valuable insights for waste management in any premises by providing weight data for the supervision of internal/external waste collectors, as well as ESG reporting. They facilitate a comprehensive understanding of waste production and collection frequency, empowering data-driven decisions to enhance sustainability KPIs, such as Waste Diversion Rate.

These reports play a pivotal role in optimising waste management strategies and promoting a more environmentally conscious operational approach. We are happy to source our data to fully customizable dashboards in Smart Analytics (Qlik platform) or send tailored e-mail reports to help you run a more efficient operation and report easily to management or publicly.

Ideal products

We recommend exploring the following solutions.

Learn more about our solution for factories & facilities

We are looking forward to learning more about what you need. Your contact information will not be used for any other purpose.

Say yes to

Through the integration of innovative technology including robust software, durable hardware, and a data-driven approach, we support the digital transformation of waste management to achieve efficiency, transparency, and sustainability.

With its team of 160+ professionals, Sensoneo provides complex software and hardware solutions worldwide, with an active presence in Europe, USA, and the MENA region. Sensoneo’s smart waste management solutions have garnered attention from countries, cities, and businesses worldwide, with installations in over 90 countries across five continents.

As the only company worldwide, Sensoneo has successfully implemented and operates IT systems for Deposit Return Schemes (DRS) in 8 countries, achieving recycling performance exceeding 90%. The deployment of smart sensors by Sensoneo is poised to contribute to the largest smart waste installation worldwide, encompassing an impressive 11,100 sensors in Madrid. Additionally, Sensoneo has designed tools to automate factory waste collection, enabling its customers to improve waste diversion rates and data reporting at their locations.