Take-Back System

Discover a comprehensive end-to-end software solution designed for the specific needs of Extended Producer Responsibility programs

Transparent

waste streams

Optimise

the use of resources

Minimising

operational tasks

Take-Back System

End-to-end and ready-to-implement software system for reverse logistics

TBS 2.0 by Sensoneo is a flexible and scalable suite of modules designed to help customers (and their customers & partners) to organize and manage their Reverse Supply Chain operations efficiently, with greater control and visibility.

Our software is more than just a transaction or pickup request processing tool. It provides comprehensive stock and warehouse management, order and transport management, and full configurability across logistics zones, tariffs, and integrations. With built-in track and trace for all transactions and a control tower that offers complete visibility into the lifecycle of each commodity and its transport, users can manage operations seamlessly without relying on service desk support.

Problems we solve

- High costs of IT solutions – OPEX solutions are unavailable, and CAPEX investments in tailored software are unaffordable.

- Poor level of digitalization – Data is often imprecise and does not flow in real time.

- Process inefficiency – Stakeholders must work across different, unconnected software platforms..

- Faulty and slow order processing – Delays occur in handling and processing orders for collection points.

Key functionalities and benefits of our solution

Modules

Powerful software for various stakeholders

Order management

The Order Management module streamlines the handling of collection orders by defining key details such as pickup location, commodity type with expected quantities, and the scheduled date and time range for pickup. It enforces order rules and validations, including location status and thresholds set per commodity type or producer ID, ensuring accuracy and compliance.

Orders can be processed in multiple ways. Automatically based on demand, on a fixed schedule, or manually triggered through the Portal or Retail App providing flexibility and efficiency across different operational needs.

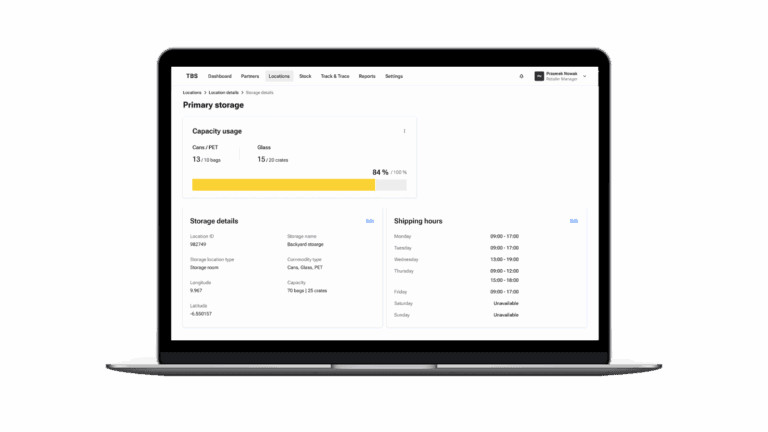

Warehouse management

The Warehouse Management module manages the receiving process across multiple sources, including vouchers, seal-codes, DRS collection points, and approved devices such as RVMs, POS terminals, and SmartDRS, while ensuring only whitelisted products are processed.

Stock build-up is automated based on defined containerization rules: adjusted per device specifications, commodity type (e.g., glass with sorted crate counts), or retailer requirements such as storage room allocation and sorting. With built-in stock visibility and adjustment features, the module also supports automatic stock allocation and door selection, enabling efficient and accurate warehouse operations.

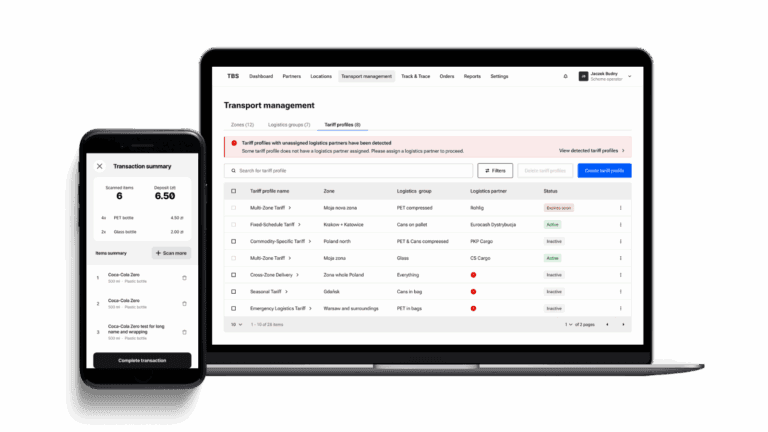

Transport management

The Transport Management module covers the full cycle of logistics operations, from planning and optimization to execution. It enables efficient transport planning by managing order and shipment allocation to logistics partners, supported by alerts and notifications for smooth coordination.

Optimization is achieved through integration with Routeneo, carriers, or third-party TMS systems, along with real-time track and trace capabilities. For execution, drivers are supported with a dedicated app and continuous tracking, ensuring visibility and control across the entire transport process.

Related solutions

We recommend exploring the following resources.

Schedule a demo call to see our Take-Back System in action

We are looking forward to learning more about what you need. Your contact information will not be used for any other purpose.

Manage waste smarter with

Built on in-house R&D, Sensoneo Smart Sensors combine IoT technology with robust hardware to deliver precise fill-level data across all waste types and container sizes. Designed and developed entirely in-house and produced in EU, our sensors ensure reliable performance, multi-network connectivity, and advanced features that support efficient and secure waste monitoring.

With its team of 160+ professionals, Sensoneo provides complex software and hardware solutions worldwide, with an active presence in Europe, USA, and the MENA region. Sensoneo’s smart waste management solutions have garnered attention from countries, cities, and businesses worldwide, with installations in over 90 countries across five continents.

As the only company worldwide, Sensoneo has successfully implemented and operates IT systems for Deposit Return Schemes (DRS) in 9 countries, achieving recycling performance exceeding 90%. The deployment of smart sensors by Sensoneo is poised to contribute to the largest smart waste installation worldwide, encompassing an impressive 11,100 sensors in Madrid. Additionally, Sensoneo has designed tools to automate factory waste collection, enabling its customers to improve waste diversion rates and data reporting at their locations.

Smart Waste Newsletter

Get monthly updates from our company and the world of waste!