Schaeffler’s Digital Waste Management Transformation

33

Containers Digitalized

490,000kg

Waste Collected

42,086kg

Emissions Savings

17

Tracked Waste Types

Schaeffler’s path to efficient waste management

Project and customer description

Schaeffler, the global Motion Technology Company, is a leading manufacturer of rolling element bearings for automotive, aerospace, and industrial applications. The Schaeffler Group views sustainability as a comprehensive, overarching topic and assumes ecological and social responsibility throughout the entire value chain.

As part of this mission, Schaeffler partnered with Sensoneo to digitalize its waste management processes. This initiative aimed to improve operational efficiency, reduce environmental impact, and create a robust data-driven waste management system.

Challenge

- Limited Visibility: Inefficient tracking of waste container fill levels led to unnecessary collections or delayed pickups

- Manual Operations: Staff spent significant time coordinating with external waste collection companies, often resulting in logistical inefficiencies

- Potential contamination issues: The system provides a way to document contamination with photographic evidence, offering transparency and preventing potential disputes with collection companies

- Ineffective Resource Use: Underutilized containers and redundant trips increased environmental and operational costs

Solution

Infrastructure Setup

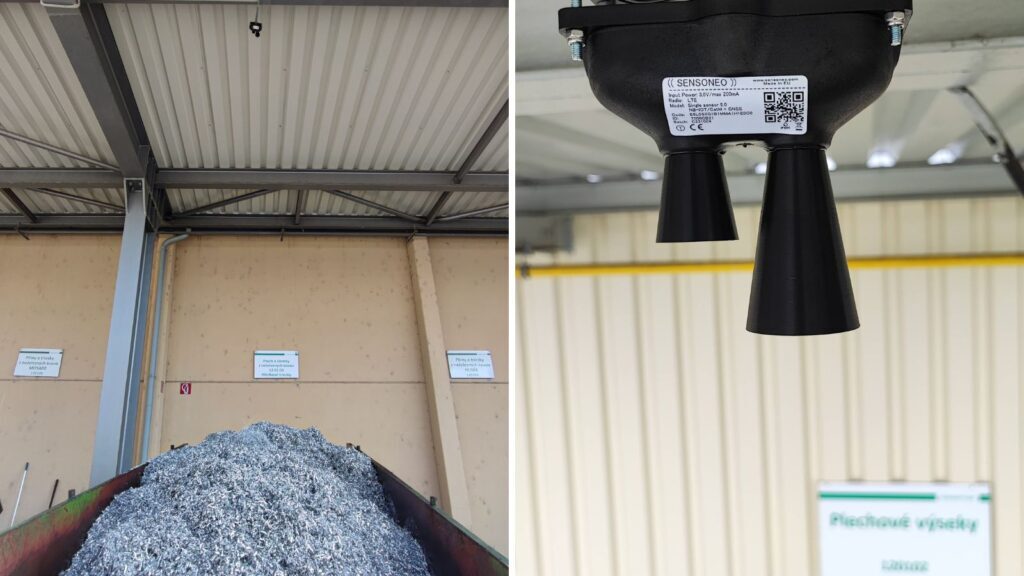

- 33 large-capacity containers: Equipped with ultrasonic sensors or another smart waste solutions to monitor fill levels in real-time

- 17 waste types tracked: Including industrial, hazardous, and valuable recyclable materials

- IoT integration: Real-time data transmission to Sensoneo’s platform for seamless waste management

- Mobile app: Used by collection staff to scan QR codes for recording weights, contamination reports, and collection details

- Digital weighing system: Ensured precise measurements and streamlined the waste tracking process

“The analytical reports provide us with clear and accurate data in one place, while allowing us to easily filter for a specific period.”

“Real-time monitoring of container status is a major advantage because we can track it remotely, saving time for staff who no longer have to physically check containers or coordinate pickups with the collection company. At the same time, the entire system from Sensoneo is seamlessly connected in an end-to-end way, from measuring container fullness to the final weighing of the waste.”

Miroslava Hanzlovicova, Head of the Waste Management Team, Schaeffler Skalica

Impact

Operational Transparency

Sensoneo’s system provided real-time visibility of container statuses, saving time for staff and improving decision-making

Data-Driven Decisions

Detailed analytical reports gave Schaeffler actionable insights into waste volumes, contamination levels, and pickup frequencies

Environmental Impact

By optimizing logistics, Schaeffler reduced emissions by over 42,000 kg during the pilot phase alone, supporting its climate neutrality goals

Streamlined Coordination

The integration of Sensoneo’s platform with external collection companies eliminated logistical inefficiencies, saving both time and resources

Reduced Contamination Risks

With photo evidence for reported contamination, disputes with waste collection companies were minimized

Key achievements

- Significant cost savings

- Prevention of unnecessary pickups

- Comprehensive data analytics on waste production and bin fill-levels

- Optimized waste collection routes

- Reduction of bin overflow incidents

Future outlook

Schaeffler plans to present the Sensoneo waste management solution to its other plants in Slovakia and the Czech Republic. Future enhancements include:

- Deployment of additional sensors to monitor more containers

- Real-time tracking of waste processing costs and revenues

- Expansion of non-standard waste workflows for materials like scrap pipes

Innovation Award

Schaeffler Skalica, a branch of a global supplier to the automotive and industrial sectors, won the Slovak Facility Management Association’s annual award in the Innovation of the Year category. The Waste Management Digitization project, which Schaeffler implemented using Sensoneo solution for industrial customers, has helped the company to shift from manual to data-driven waste management within months and to achieve remarkable results.

Smart Waste Newsletter

Get monthly updates from our company and the world of waste!