Reverse Logistics Software for transparent and automated workflow management

Digitalisation

Introduce automation, transparency and efficiency

Stakeholders

PROs, Take-Back operators, DRS operators, producers

Data Collection

For invoicing, reporting, and service verification

Optimise your Reverse Logistics with a fully digital platform

for your specific needs

Modern reverse logistics doesn’t have to be complex. Our platform gives companies full visibility, automation, and control, co you can manage all reverse flows efficiently, reliably, and with confidence. Track reverse workflows in real time, automate repetitive tasks, and ensure every process step is documented and auditable. Whether you manage large return volumes or complex reverse chains, our solution grows with your requirements, and you can confidently demonstrate compliance at any time.

Reverse Logistics Platform for Producer Responsibility Organisations

Reverse Logistics Platform for Take-Back Operators

Reverse Logistics Platform for Deposit Return Systems

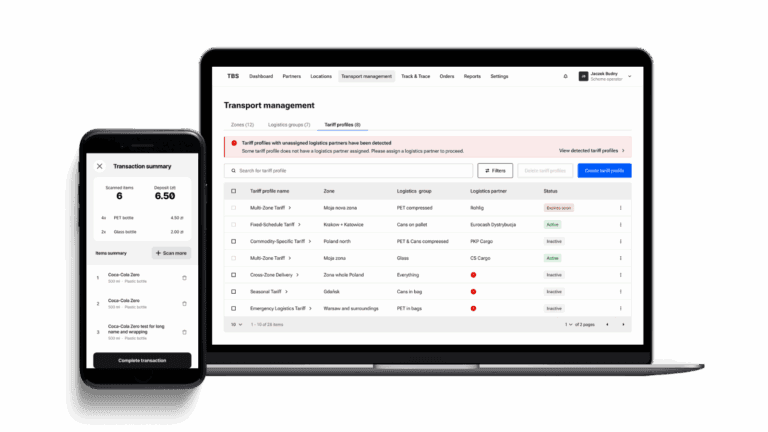

A complete Reporting & Billing Software Platform for PROs and Reverse Logistics Organisations

Client portal is a powerful, intuitive software solution that centralizes registration and reporting, streamlines compliance workflows, and automatics financial operation within a secure and user-friendly environment. Client Portal enables to easily create and manage profiles, register products and submit detailed reports on the volumes. The portal ensures accurate and timely data collection that aligns with compliance requirements, facilitates billing, and invoicing. The portal also provides analytics and reports that support better operational decision-making.

Take-Back Software solution to gain full visibility across your reverse logistics chain

See your entire reverse logistics process at a glance from the initial request to final processing. The solution provides smart tools for all stakeholders: Operator, Collection Points, Logistics Partners and Processing sites. Collection Marketplace easily solves demand & supply for waste transport. Mobile apps collect data every step of the process building transparent waste streams from the source all the way to processing. Route Planning plans the shortest collection routes and navigates drivers from pickup to pick up. The solution minimizes administrative tasks, encourages transparency & traceability.

OPEX Savings | Transparent Invoicing | Less Administrative Workload | Modern & UX friendly tools

Discover modules of the Take-Back system for reverse logistics

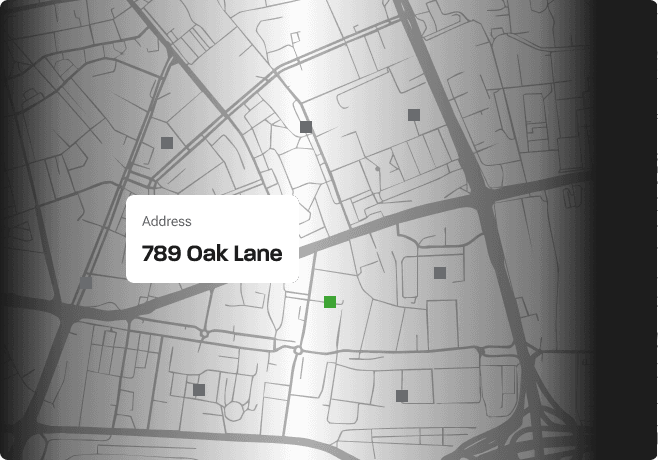

Collection Points

The Manager or Operator places a pickup request (or requests) via Mobile App. The request appears on the Marketplace where Logistics partners wait to “catch” their orders. Once the Driver is assigned, Collection Point receives notification including details (who & when). They also see a list of all past, assigned, open or draft requests.

The Take-back operator does not need to interfere in the process.

Quick & easy workflow to place a pickup request | Simple & user-friendly mobile app for all tasks | Transparent waste streams | Mobile app & Web portal

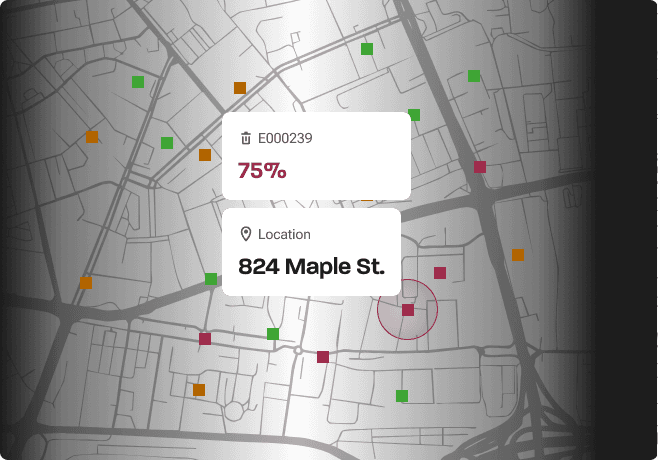

Collection Bins

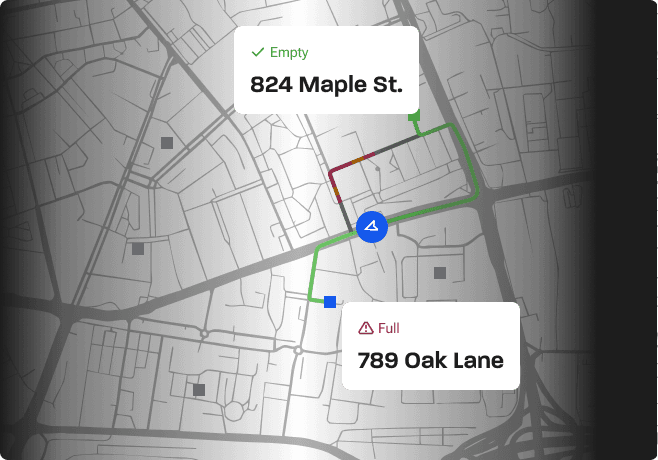

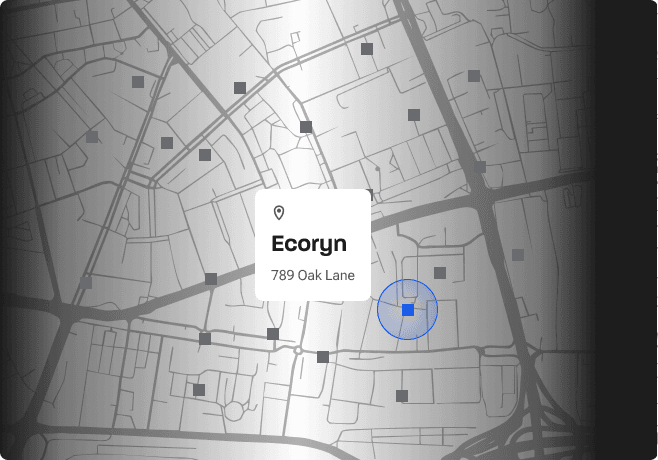

Collection Bins are equipped with Smart Sensors measuring fullness 24x a day. The system automatically places a pickup request once the bin is almost full. Pickup requests appear on the Marketplace where Logistics partners wait to “catch” the order. Pickup requests can be placed also according to a fixed schedule. Besides fullness, the sensor provides a service verification and has a built-in fire & tilt alarm.

Fully automated workflow | Transparent waste streams | Lower collection costs | Interactive bin map for public

Logistics Partners

The solution by Sensoneo helps you better plan & optimize your collection capacities, and increase profitability.

All pickup requests appear on the Marketplace. The Operator signs up for all relevant orders in Web Portal, divide them into Collection Routes and then assign routes to Drivers. Drivers access task via Driver App, log in discharges and follow step-by-step navigation. Sensoneo solution significantly cuts collection costs – algorithms fill up the vehicle & plan the shortest route. The Take-back operator does not need to interfere in the process.

Quick & easy workflow to signup for pickups & to log in discharges | More profit per drive | Step-by-step driver navigation | Transparent invoicing

Processing Facility

Manager or Stock-keeper quickly receives and logs in discharges in Mobile App and inputs data for further reporting. Manager has an overview of all delivered and assigned waste. For unprocessed waste, they request transport- place pickup requests on the Marketplace for Logistic Partners same as Collection Points. The Take-back operator does not need to interfere in the process

Reliable data on discharges | Quick & easy workflow to place pickup request | Transparent invoicing | Mobile app & Web portal

Key benefits

01

Transparent Waste Streams

02

Rich Data Collection

03

OPEX Savings

04

Task Automation

05

Easy Task Management

06

Marketplace for pickups

Ideal products

We recommend exploring the following solutions.

Quick Summary

Extended Producer Responsibility (EPR)

Extended Producer Responsibility (EPR) is a policy that defines the responsibilities for producers, manufacturers, and importers of products regarding the treatment and disposal of products once they reach the end-of-life stage. EPR encourages producers for “lower environmental impact” design and environmentally friendly disposal.

Some producers are fulfilling the EPR requirements using their internal forces. However, majority cooperate with Producer Responsibility Organizations that provide full-management of post-consumer take-back, collection, and recycling and ensure the producer’s compliance with the regulations.

Reverse Logistics

Producer Responsibility Organizations (PRO)

Producer Responsibility Organizations are collective nationally operating bodies that provide compliance with the legislative requirements of producers on their behalf and against a financial contribution on their part. PROs organize post-consumer take-back, ensure recovery and recycling targets, promote eco-design, educate on waste prevention, verify the data and report to national authorities.

The legal responsibility of PROs for the fulfilment of required targets puts high expectations on their knowledge, management, and operations. Digital transformation of some of the core activities can significantly relieve the manual workload, enhance transparency, automation, and accurate reporting.

Reverse logistics plays a key role in enabling PROs and producers to meet these obligations effectively. By managing the reverse flow of products, from consumer returns and collection points back through sorting, transport, and recycling. Reverse logistics ensures that end-of-life products are handled in line with regulatory targets and sustainability goals. When supported by digital tools, it becomes not only a compliance mechanism but also a driver of efficiency, cost savings, and measurable environmental impact.

Learn more about our IT solution for Reverse Logistics

We are looking forward to learning more about what you need. Your contact information will not be used for any other purpose.

DRS IT System by

support schemes and circular economy in 8 countries worldwide, with our software daily impacting the lives of more than 165 million people. Billions of returned PET bottles and aluminum cans actively contribute to cleaner rivers, forests, and nature.

With its team of 160+ professionals, Sensoneo provides complex software and hardware solutions worldwide, with an active presence in Europe, USA, and the MENA region. Sensoneo’s smart waste management solutions have garnered attention from countries, cities, and businesses worldwide, with installations in over 90 countries across five continents.

As the only company worldwide, Sensoneo has successfully implemented and operates IT systems for Deposit Return Schemes (DRS) in 9 countries, achieving recycling performance exceeding 90%. The deployment of smart sensors by Sensoneo is poised to contribute to the largest smart waste installation worldwide, encompassing an impressive 11,100 sensors in Madrid. Additionally, Sensoneo has designed tools to automate factory waste collection, enabling its customers to improve waste diversion rates and data reporting at their locations.