Efficient and sustainable waste management for industrial premises

Efficiency and safety in factories is strongly impacted by waste management

Overflowing bins cause costly delays, while collecting half-empty bins disrupts workflows. Inefficient routes waste resources, and limited data makes optimization and sustainability harder to achieve.

Addressing these challenges requires an innovative approach to waste management that prioritizes efficiency, sustainability, and data-driven approach.

Sensoneo solution

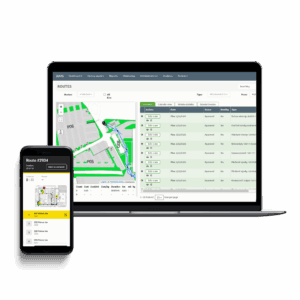

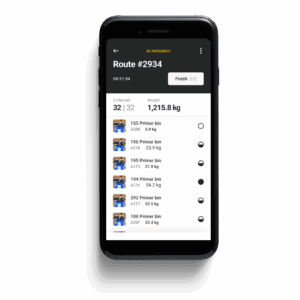

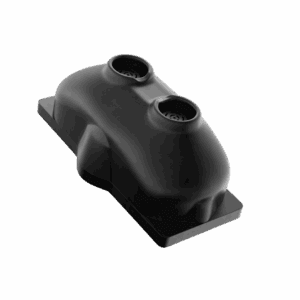

Sensoneo’s Factory Waste Management solution is designed specifically for the manufacturing industry. By leveraging smart sensors and real-time data, it optimizes waste collection routes, reduces costs, and ensures smooth operational flow. The system delivers accurate insights into waste volumes and contamination levels, helping factories comply with regulations, meet sustainability goals, and achieve waste traceability.

The solution combines actionable analytics with operational efficiency. Through the Collector App, factories receive detailed reports that support ESG reporting, optimize waste strategies, and improve sorting practices to reduce contamination and increase diversion rates. On the shop floor, features such as fullness alerts and route planning on factory layouts streamline waste collection, cut unnecessary costs, and enhance workforce efficiency.

Ideal products

Benefits

- Just-in-time collection

- Increased Waste Diversion Rate

- Saving money on unnecessary collections

- Reduction of waste contamination

- No more overflowing bins

- Control over collectors

- Quality of sustainability reporting

Latest use cases

Fill-level monitoring of bins and dumpsters at the university campus

Read more

Efficient reverse logistics system for the collection of used tyres

Read more

Waste fill-level monitoring for paper shredding companies

Read more

Data-driven control of waste in cities and municipalities

Read more

Smart Waste Newsletter

Get monthly updates from our company and the world of waste!