Understanding Industrial Waste: Types and Sources

What Is Industrial Waste?

Industrial waste includes unwanted materials that come from industrial activities like manufacturing, mining, energy production, and food processing. These wastes differ from municipal waste, which mostly comes from homes and businesses. Industrial waste usually appears in large amounts and includes a wide variety of substances. Some of these substances can be dangerous and need special handling.

Major Types of Industrial Waste

Solid Waste:

Solid industrial waste covers items such as scrap metals, plastics, packaging materials, paper, sludge, and construction debris. For example, when a metal fabrication facility operates, it produces metal shavings and leftover pieces as solid waste.

Liquid Waste:

Liquid industrial waste includes wastewater, oils, solvents, acids, and other chemicals that come from production or cleaning. Energy plants and chemical manufacturers often create large amounts of liquid waste.

Hazardous Waste:

Hazardous waste contains materials that can harm people or the environment. Examples include heavy metals like lead and mercury, solvents, pesticides, and some byproducts from making electronics. You must handle and dispose of these materials with care.

Non-Hazardous Waste:

Non-hazardous waste does not create immediate risks. Food scraps from food processing plants and cardboard packaging from assembly lines belong to this group.

Chemical Waste:

Chemical waste comes from industries that use or produce chemicals. This includes used solvents, acids, alkalis, and reactive compounds. Industries such as pharmaceuticals, paints, and plastics contribute a lot to chemical waste.

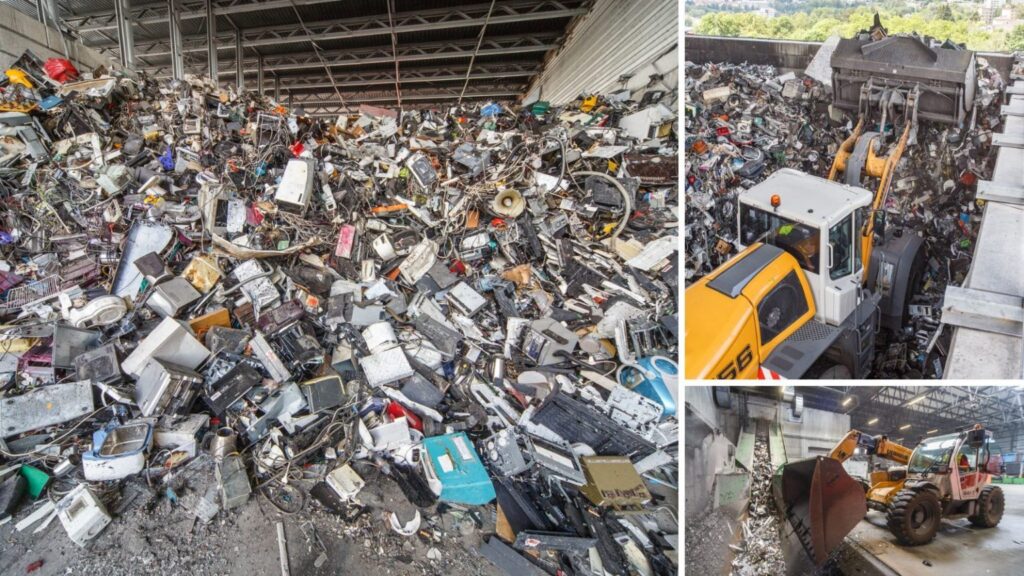

Electronic Waste (E-Waste):

Electronic waste includes old equipment, circuit boards, and batteries from electronics manufacturing. These wastes often have dangerous parts but can also contain useful metals for recycling.

Primary Sources of Industrial Waste

Main sources of industrial waste include:

- Manufacturing facilities: These create many types of waste, such as metal scraps and used solvents.

- Energy plants: These produce ash, sludge, and leftover chemicals.

- Food and beverage processing: These processes result in organic waste like peels, pulp, and wash water.

- Chemical plants: These release residues, used solvents, and process chemicals.

- Electronics manufacturing: These operations generate e-waste, including faulty circuit boards and used batteries.

Example:

A metal fabrication plant creates more than one type of industrial waste. It produces scrap metal, which is a form of solid waste, and also uses solvents that become hazardous liquid waste during production.

You can see that industrial waste comes in many forms and from many sources. Each type needs specific management to handle it safely and responsibly.

Environmental and Social Impacts: Risks to Ecosystems and Public Health

Contamination of Natural Resources

When industries do not handle waste properly, soil, water, and air can become polluted. Hazardous chemicals such as heavy metals, solvents, and persistent organic pollutants often seep from waste sites into groundwater and rivers. This process can harm aquatic ecosystems and make drinking water unsafe. Scientific research shows that industrial waste can increase the amount of toxic substances in local waterways. These toxins can disrupt aquatic life and reduce the number of different species living in the area. For example, if solvents and heavy metals from factories enter the groundwater, that water may no longer be safe for people to drink or use for farming.

Air Quality and Toxic Emissions

Industrial waste can release pollutants into the air, including volatile organic compounds and tiny solid particles called particulate matter. These pollutants can spread over large areas, affecting people who live far from the original source. Breathing in these substances over long periods can lead to respiratory diseases, problems with the heart and blood vessels, and a higher chance of developing cancer, especially for those living near industrial sites.

Public Health Risks for Nearby Communities

People who live close to industrial areas face higher health risks because they are exposed to polluted air, water, and soil. Studies show that these communities have more cases of respiratory infections, skin problems, and developmental issues, particularly among children and people who are more sensitive to toxic substances.

Real-World Example

In one documented case, a manufacturing site disposed of solvents in the wrong way, which caused groundwater contamination in the nearby community. Residents experienced more illnesses, and local officials had to supply clean water to prevent more health problems.

Managing industrial waste correctly helps protect local ecosystems and keeps communities safe from these known risks.

Waste Quantification and Data Reporting: Quantifying and Monitoring Waste Output

Measuring Industrial Waste

To manage industrial waste well, you first need to measure it accurately. When you know how much waste your factory produces, you can follow environmental rules, set goals to reduce waste, and find ways to fix production problems. If you do not collect reliable data, you cannot see if your efforts work or prove that you follow the rules.

How to Measure Waste Output

You can use direct and indirect methods to measure industrial waste. Direct methods include weighing waste as it is produced, using floor scales for solid materials, or flow meters for liquids. Indirect methods estimate waste by looking at the amount of raw materials used, the final production output, or past data patterns. You might use indirect methods when direct measurement is too difficult.

When dealing with hazardous waste, you must follow strict laws. For example, the U.S. Resource Conservation and Recovery Act (RCRA) requires you to keep exact records about the type, amount, and handling of every hazardous waste stream.

Collecting and Reporting Waste Data

Factories gather waste data in different ways. Some use manual logbooks or spreadsheets, while others choose digital tools. Automated systems, like barcoded bins, flow sensors, and weighbridges, can record data instantly and reduce mistakes. Factories usually put this information into monthly or quarterly reports. These reports help them meet local regulations and guide their own efforts to use resources more responsibly.

Staying Compliant and Improving Over Time

Regulations tell factories how and when to report waste data. Detailed records help track waste from its source and make audits easier. When you monitor waste regularly, you can compare your performance over time, find ways to save money, and focus on cutting waste where it matters most.

Example: How a Factory Tracks and Reduces Waste

A manufacturing plant uses digital forms and floor sensors to record the amount of waste each department creates every day. At the end of each month, staff review this data to prepare compliance reports and to spot problems, like too much packaging or steps in the process that create extra waste. This routine helps the factory meet legal requirements and make progress toward its environmental goals.

When you set up clear systems for measuring and reporting waste, you give your facility the tools it needs to manage waste better and keep improving how it operates.

Waste Diversion and Sorting: Maximizing Diversion and Reducing Contamination

Waste Diversion Rate

Waste diversion rate measures how much waste you keep out of landfills by recycling, composting, or reusing materials. You can calculate this rate using the formula:

Waste Diversion Rate (%) = (Weight of Diverted Waste / Total Waste Generated) × 100

For example, scientific research shows that effective waste diversion in industrial settings can lower landfill disposal by more than 60%. This reduction helps limit environmental harm and meets sustainability targets.

Sorting Processes: Manual, Automated, and Centralized Systems

Sorting waste correctly helps you increase your diversion rate. Industrial facilities use several methods to sort waste:

- Manual Sorting: Workers separate waste at the source or at special sorting stations. This method lets you identify items quickly, but you need to train staff regularly and monitor the process closely.

- Automated Sorting: Machines like conveyor belts, optical sorters, and magnetic separators sort metals, plastics, and electronics. These tools help increase sorting speed and accuracy.

- On-site vs. Centralized Sorting: On-site sorting lets you divert waste immediately. Centralized sorting uses advanced equipment to manage complex waste streams, which often increases the amount of material you can recover.

How Proper Sorting Affects Diversion

When you separate recyclables (like metals and plastics), compostables (such as food scraps), and items that can be reused from landfill waste, you can reach higher diversion rates. Industry data shows that strong sorting systems can help you divert 50–70% of your waste. For instance, a factory might recycle metal scraps, compost cafeteria waste, and reuse packaging, achieving a 60% diversion rate.

Contamination: Causes and Results

Contamination happens if you mix incompatible materials, such as hazardous chemicals with recyclables. Even small amounts of contamination can make recyclable materials unusable. This can lead to more landfill disposal and may break environmental laws.

Examples of contamination in industrial settings include:

- Putting oily rags with paper waste

- Mixing hazardous chemical residues with clean recyclables

- Throwing away electronic parts with general waste

Ways to Reduce Contamination

To recycle efficiently and follow regulations, you need to control contamination. These steps can help:

- Staff Training: Teach employees how to separate waste properly. Regular training reduces mistakes and increases the amount of waste you can divert.

- Clear Labeling: Use color-coded bins and clear signs. This helps everyone know where to put each type of waste.

- Process Improvements: Set up clear procedures and do regular checks. This keeps sorting consistent and helps you find ways to improve.

Many factories that combine these methods have reached diversion rates above 60%, as shown in studies and industry reports.

Example:

A manufacturer manages to divert 60% of its waste by recycling metal shavings and composting cafeteria scraps. The company trains staff often and uses clear labels on bins, which keeps oily rags out of the paper recycling and helps keep streams clean.

Boosting Operational Efficiency: Streamlining Waste Handling Processes

Enhancing Productivity Through Efficient Waste Management

Industrial waste management affects how well manufacturing operations run and how much they cost. When you streamline waste handling, you help prevent delays and keep production moving smoothly. Managing waste efficiently also helps companies follow environmental laws and lowers risks during operations.

Key Strategies for Process Optimization

1. Process Optimization and Source Reduction

You can make your manufacturing processes more efficient by reducing waste at the source. This includes changing how you use raw materials, upgrading equipment, and using better control systems. These steps lower the amount of waste you produce and make it easier to handle what remains. For example, if you replace hazardous materials with safer options or switch from organic solvents to water-based ones, you decrease how much waste you need to treat.

2. Coordinated Collection and Storage

When you match waste collection times with your production schedule, you avoid overflow and cut down on unnecessary delays. This kind of scheduling removes waste before it piles up, helps keep the workplace safe, and limits the chances of environmental problems. Good storage methods, like using clearly labeled bins and keeping different waste types separate, make collection and handling faster and more accurate.

3. Route and Logistics Optimization

If you plan and improve the routes for moving waste inside your facility, you can cut down on transport time and need less labor. Research shows that having dedicated pathways for waste and reducing traffic in these areas lowers costs and reduces the risk of accidental mixing or spills.

Benefits of Streamlined Waste Handling

When you set up efficient waste handling procedures, you save time and resources during collection, transport, and storage. This efficiency also helps you avoid breaking regulations because waste is removed properly and on schedule. Plants that plan waste collection around their production activities usually face fewer shutdowns and meet environmental standards more consistently.

Example:

A factory schedules waste pickup right after its busiest production shifts. This prevents containers from overflowing and reduces unplanned stoppages. As a result, the factory has seen lower disposal costs and improved compliance with regulations.

By managing industrial waste effectively, you can help your factory or plant run more smoothly and meet modern production goals.

Smart Waste Management and IoT Solutions: Implementing Automation and Real-Time Monitoring

Harnessing IoT for Intelligent Waste Management

You can use Internet of Things (IoT) technology to make industrial waste management more efficient. IoT systems use devices like fill-level sensors, RFID tags, and wireless transmitters. These devices monitor waste containers and collection points across a facility. Sensors collect data on how full each bin is, as well as temperature and gas emissions. This information updates in real time, so facility managers always know the current status of waste collection areas.

Automation and Real-Time Insights

Automated waste systems connect IoT devices to a central dashboard. This setup lets managers see waste build-up patterns as they happen. When a container gets close to full, fill-level sensors send out alerts. This helps managers schedule pickups only when needed, which means fewer unnecessary trips for waste collection. According to a 2024 study in Scientific Reports (Nature), IoT-based systems can cut waste collection trips by up to 40%. This reduces both fuel use and operating costs.

Benefits of Smart Solutions

Smart waste management brings several advantages to industrial settings:

- Lower Labor and Maintenance Needs: Automated messages mean staff do not have to check bins manually. Workers can spend more time on other important tasks.

- Prevention of Spills and Overflows: Alerts arrive before containers overflow, which helps prevent spills and reduces safety risks.

- Better Compliance: Real-time tracking makes it easier to keep precise records for environmental reports and audits.

- Efficient Resource Use: Data from sensors allows facilities to adjust collection routes, choose the best spots for bins, and plan maintenance more accurately.

Example Application

Imagine a manufacturing plant using bins fitted with fill-level sensors and wireless transmitters. When a bin gets close to being full, the system sends a notice directly to staff. This process helps workers collect waste before it overflows, keeps the facility within safety guidelines, and improves waste management efficiency—all without needing to check bins by hand.

This section explains how facilities can use technology to automate waste collection, monitor containers in real time, and improve the entire waste management process.

Data-Driven Approaches and Future Innovations: Leveraging Analytics, AI, and Emerging Technologies

Advanced Analytics for Informed Decision-Making

Today, industrial waste management uses advanced data analytics to guide daily decisions and support sustainability efforts. When you collect data from production lines, waste streams, and disposal processes, you can apply statistical modeling and machine learning. These tools help you predict how much waste a factory will produce, find where resources are being used poorly, and improve how resources get allocated. For example, predictive models use past production data to estimate when waste levels might peak. This lets you adjust production schedules or processes in advance so you can reduce waste and avoid expensive overflows.

Artificial Intelligence and Automated Sorting

Artificial intelligence (AI) brings automation to waste management through advanced sorting systems and real-time waste classification. Machine vision and AI-powered robots sort items on conveyor belts by type, such as recyclable, hazardous, or non-recyclable materials. This process keeps contamination low and helps more waste get recycled. AI systems learn from the data they gather during daily operations, so they keep improving sorting accuracy and can adapt as waste streams change.

Integration with Sustainability and ESG Goals

Data-driven methods help facilities connect waste management with Environmental, Social, and Governance (ESG) goals. You can use analytics dashboards to monitor key performance indicators, including how much waste is diverted from landfills, the facility’s carbon footprint, and compliance with regulations. These tools make it easy to report progress clearly to stakeholders and regulators. They also let you compare your facility’s performance to industry standards.

Future-Ready Technologies: Blockchain and Circular Economy Models

New technologies continue to change industrial waste management. Blockchain platforms provide secure and transparent tracking for waste streams. With blockchain, you can follow waste from its source all the way to disposal or recycling. This process limits illegal dumping and inaccurate reporting. Digital platforms that support circular economy models encourage you to reuse and regenerate materials. This approach shifts away from the old linear model of disposal and instead supports sustainable cycles for resources.

Example:

A factory uses predictive analytics to spot when waste surges will happen before major maintenance events. With this information, the factory can change its production and waste handling plans ahead of time. This approach leads to lower waste levels and helps the factory stay within environmental guidelines.

Latest waste library articles

5 Biggest organized waste crimes worldwide

Environment

How can the Deposit Refund System look like?

The Evolution of EPR Compliance and PRO Software Systems

EPR Compliance, Extended Producer Responsibility (EPR)

Understanding the link between waste and climate change

Environment

Smart Waste Newsletter

Get monthly updates from our company and the world of waste!