Smart monitoring of textile bins for efficient collections

The textile waste collection business is one of the most demanding industries

Textile waste collection companies must consistently meet challenging operational targets to stay competitive, maintain profitability, and secure new contracts.

Guaranteeing the daily collection volumes necessary for smooth logistics and warehouse management is not just a goal—it’s a crucial requirement. However, the road to achieving this is filled with difficulties. Increasing operational costs are putting pressure on budgets, while the lack of real-time data complicates on-time collections, leading to inefficiencies in pickups. Overflowing bins not only attract complaints but also jeopardize partnerships with schools, shopping malls, and other host locations by creating mess and littering around the bins.

Frequent theft and robberies of textile bins disrupt operations and profits, adding yet another layer of complexity to an already tough business. Outdated route planning systems further complicate these issues, making it difficult to optimize collections and meet operational demands.

In an industry where every kilogram counts, ensuring clean and well-maintained collection sites while consistently meeting volume targets is essential for both operational success and long-term survival.

-29% of time

Required for the collection of 1 tonne of material for Textile Waste Collector with more than 1,300 bins and 3,000 tonnes of collected material annually

Sensoneo solution

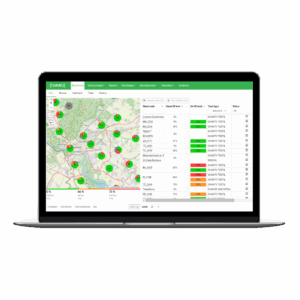

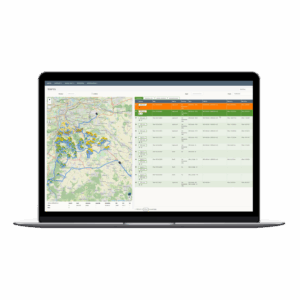

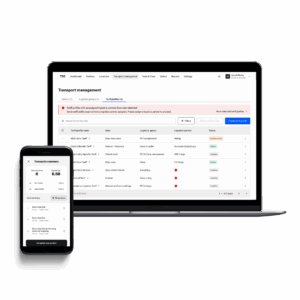

Our innovative solution for textile waste collectors combines smart sensors with an advanced waste management software platform to enable efficient planning of waste collections. Textile waste bins are unique due to their irregular filling cycles—the rate at which they fill is unpredictable. This unpredictability complicates the pickup process, placing significant financial and logistical demands on waste operators and managers. Real-time remote monitoring of fill levels can streamline operations and reduce costs.

At the core of our solution are smart bin sensors installed in textile waste bins, continuously monitoring their fill levels. These sensors use ultrasonic technology to deliver precise measurements of waste levels. The collected data is transmitted in real-time to our Waste Management System (WMS), providing actionable insights that empower data-driven decision-making.

Ideal products

Benefits

- Cost efficiency with dynamic waste collection, no unnecessary routing

- Collection of only full bins, saving resources on bins in remote locations

- Ability to guarantee a needed daily volume of collected material

- Theft prevention and security

- Smooth logistics planning and warehouse management thanks to comprehensive data

- Competitive advantage thanks to on-time collection and clean public spaces with no litter and overflowing bins

- Rightsizing of frequencies, capacities or locations

- Reducing CO2 emissions, relieving traffic congestion

Selected success stories

Monitoring textile waste bins with smart sensors

Smart Monitoring Boosts TexCycle’s Textile Collection Across CEE

Proven performance of bin sensors during harsh Canadian winters

Smart Waste Solutions Enhance Paper Collection in Rosenheim

Latest use cases

Efficient waste management for highway service areas

Read more

Data-driven control of waste in cities and municipalities

Read more

Fill-level monitoring of wastewater in cesspit and septic tanks

Read more

Fill-level monitoring of bins and dumpsters at the university campus

Read more

Smart Waste Newsletter

Get monthly updates from our company and the world of waste!