Fill-level monitoring of grain storage feed bins for efficient farm management

Effective grain storage in feed bins is essential for maximizing yields and profitability

Misaligned harvesting schedules, inefficient transportation logistics, and a lack of insight into optimal times for refilling silos or selling commodities can hinder operations and profitability. Without remote monitoring, farmers are left in the dark about the status of their silos when away from the farm, making it nearly impossible to make timely, informed decisions.

The absence of reliable data further complicates the ability to optimize storage strategies, allocate resources efficiently, and plan effectively for future harvests. Addressing these pain points is critical for transforming silo management into a streamlined, data-driven process.

Sensoneo solution

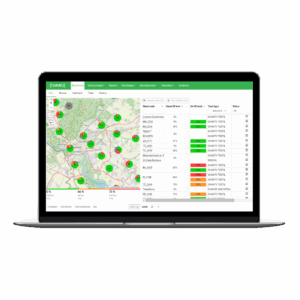

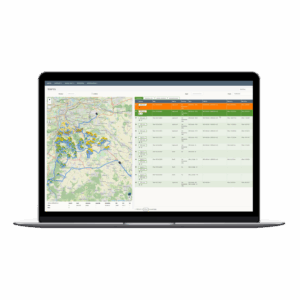

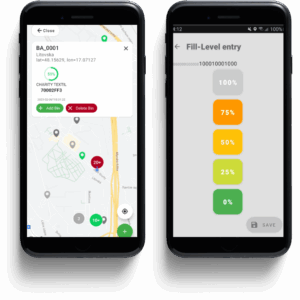

Sensoneo’s fill-level monitoring solution can be invaluable for farmers managing their silos. Sensoneo’s Smart Sensors continuously monitor the fill level of silos up to 12 meters deep, ensuring farmers are aware of the remaining quantity of their material commodities. With up to 24 updates per day, farmers receive real-time data on their silo fill levels, preventing any sudden shortages, so they can properly organize their businesses – whether it means feeding animals or distribution of bulk products such as grain or sanding salt. A small and powerful solution uses a minimum of energy to provide farmers with the critical data they need.

Ideal products

Benefits

- Acurate and timely updates on the fill level

- Precise monitoring and management of commodities

- Optimized operations

- Remote monitoring

- Data analysis and insights

- Ability to ensure smooth refill if required

Selected success stories

Latest use cases

Efficient WEEE collection and management with smart technology

Read more

Fill-level monitoring in used cooking oil (UCO) collection

Read more

Efficient reverse logistics system for the collection of used tyres

Read more

Fill-level monitoring of bins and dumpsters at the university campus

Read more

Smart Waste Newsletter

Get monthly updates from our company and the world of waste!