Reference: Smart waste management for tractor factory in Germany

Global agriculture machinery manufacturer monitors its waste in Germany using Factory Waste Management from Sensoneo

Project and customer description:

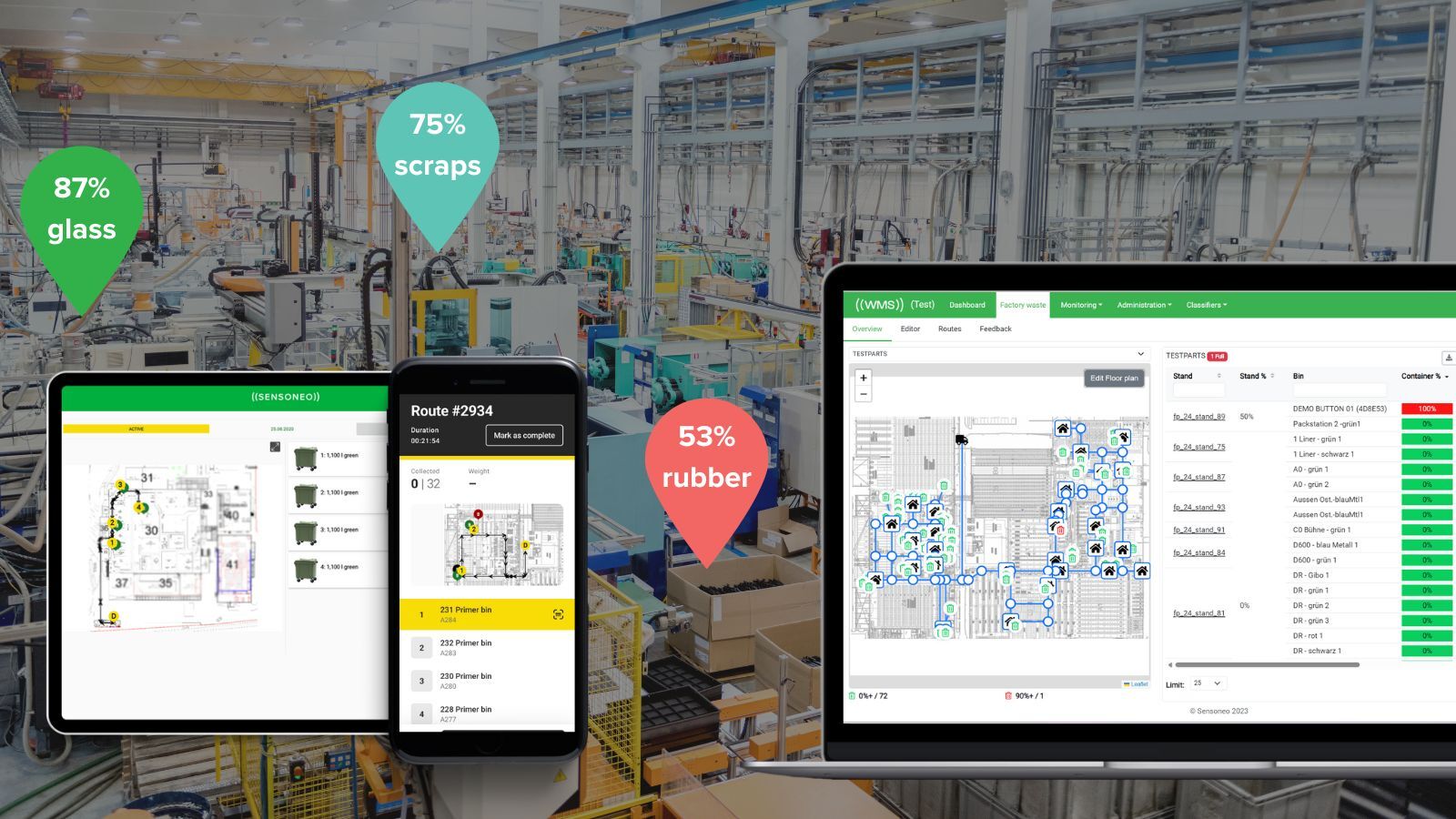

Sensoneo has designed an intelligent waste collection system for two plants of an international agricultural machinery manufacturer – for efficient waste collection processes, higher recycling rates, and lower costs.

Together with Heliot Europe, the European operator of the Sigfox network, Sensoneo has implemented a holistic digitalized waste management system for two plants of an international agricultural machinery manufacturer in Germany. Thanks to the sophisticated sensor technology and intelligent software, the system automatically detects waste generation patterns and helps employees collect what are now around 400 waste containers. In the process, it provides valuable data for strategic decisions, such as improving recycling rates – reliably in an industrial environment with Sigfox’s 0G network.

Challenge:

Around 50 million tonnes of waste are generated in industry annually – in Germany alone. Complex processes are required to collect and dispose these quantities in factories and production sites or to feed them into the recycling cycle and record them in an ESG system.

In the spacious production halls of the factory of one of the world’s largest agricultural machinery manufacturers, the individual components are assembled into tractors, combine harvesters, and other large agricultural implements. Every step is precisely timed. Precision, efficiency, and productivity are enormously important in all steps to ensure the quality for which the company is known – also when it comes to waste. Containers are always placed between the individual workstations to collect recyclable materials such as metal foils and other plastic materials, paper, and cardboard as well as residual waste.

“Until now, the containers were simply collected at fixed intervals according to fixed emptying schedules, no matter how full they were. This meant that the employees had to approach and check the several hundred waste containers individually,” says Martin Halasz, Project Manager at Sensoneo. “The little data on waste generation was collected in simple Excel sheets, which is not sufficient for ESG reporting. This was inefficient and did not meet the requirements of modern waste management – it made it almost impossible to improve collection processes and recycling rates, for example.”

“We first had to understand the entire processes in the two plants and the requirements of our customer. It was important to redesign the collection processes so that they disrupted the actual production processes as little as possible. Additionally, the system was to provide our customer with detailed data on waste quantities and quality. This is an important basis for ESG reporting, permanently improving the waste diversion rate in the plant and optimizing the costs of waste management.”

Martin Halasz Project Manager at Sensoneo

Solution:

System for tracking more than 400 waste containers

At the heart of the solution is Sensoneo’s smart waste management software. Using the sensors and smart buttons, the system records the collection requests, fill levels, and waste quantities of the waste containers in the plant, processes them, and thus recognizes waste generation patterns. The platform offers the responsible plant managers deep insights into the waste management processes and the possibility of tracking waste quantities, evaluating the data, importing it into the software platform, and operationally optimizing the collection or adapting it to new process flows on the production lines. Comprehensive data are used for ESG reporting. Factory Waste Management solution includes also a drivers app. As a navigation tool, it calculates the fastest routes to the containers to be collected. This not only helps the driver to empty the containers quickly, smoothly, and in a time-saving manner, but also saves unnecessary journeys, significantly reduces traffic in the plant, and prevents interruptions in operations.

Impact:

“Tests at the plant have shown that it is important for internal processes to collect waste within an hour of pressing the smart button,” explains Martin Halasz. “Our smart waste management software, in combination with the navigation app for the drivers, creates the basis for perfect timing and optimizing waste collection at the plant. In addition, the app helps to increase the waste diversion rate. For example, at each container, drivers are prompted to provide real-time feedback on the cleanliness of the waste via the app. If, for example, it is repeatedly noticed at a station that waste is dirty and not sufficiently separated, those responsible can look at the situation on-site and find solutions to improve waste quality.”

Implementation of the solution at the factory took only few months. With the positive results of the just-in-time waste management solution at the German sites, the agricultural machinery manufacturer is creating new standards in its plants. As a result, the company now has an accurate overview of the waste generated in its production. This not only gives the plants a detailed basis for their ESG reporting but also a powerful tool to improve recycling rates and to accurately track and reduce waste management efforts and costs. Thus, the investment is not only worthwhile from an environmental and efficiency point of view but will also pay off financially in the medium and long term.

Partners:

Heliot Europe – European operator of the Sigfox IoT network

More references

We help customers manage waste smarter

-

Smart waste sensors deployed across BART facilities

United States - 50.7 million Annual passenger trips

- 50 Number of stations

- 131 Miles of track

-

Digital transformation of waste management at Schaeffler production plant

EU - 33 Containers Digitalized

- 490,000kg Waste Collected

- 42,086kg Emissions Savings

-

From 7 to 4 FTEs: Workforce efficiency with Smart Waste Solutions at the European fulfillment center

EU - 85 207€ Yearly Cost Savings on FTEs per facility

- 35 754kg CO2 Savings per facility

- 99.82% Waste Diversion Rate per facility