Automation of waste collection

Factory Waste Management

Waste is produced all over the production lines in the factory (unpackaging, cutting, clipping …). As material logistics and the whole production flow are carefully coordinated, such attention needs to be paid to the waste collection as well. Sensoneo introduces tools designed to automate Waste collection in a factory with ease.

We help you in achieving waste traceability, allowing you to obtain valuable information on the type, amount, and location of waste generated in your facility. Thanks to our solution, you stay ahead of the curve and achieve your sustainability KPIs, while improving waste diversion rate. Furthermore, you avoid contamination and optimize your waste collection to save costs and prevent disruptions in the workflow. Additionally, all the data we help you to gather, enables you to create addressable measures towards your employees like training and education about proper sorting.

Our automated waste collection tools make it easy to coordinate and monitor waste production throughout your production lines. With our remote fill-level monitoring, you can track waste levels in real time and optimize the collection. Our Smart Waste Management system and collection app streamline the process, allowing drivers to efficiently navigate and collect waste on the floor plan dynamically.

Sensoneo provides smart enterprise-grade waste management optimized solutions for businesses and cities to efficiently manage the waste lifecycle, improve the environment and well-being of people. Factory Waste Management solution combines Smart Buttons and/or Smart Sensors, Smart Waste Management System, a powerful software cloud-based platform, and a Collection App for Drivers.

Waste challenges for factories

01 Delayed collection of overflowing bins disrupts your optimized logistics flow

02 Unnecessary collection of half-empty bins disrupts your logistics line workforce

03 Unnecessary routes are wasting your resources and increasing danger to safety

04 Lack of data about the volume of the waste produced at each logistic step

05 Contamination tracking in order to increase your sustainability goals

Key functionalities and benefits of our solution

Increased efficiency of collection (lower expenses)

Increased quality of ESG Reporting

Collector supervision (internal and external)

Waste infrastructure overview (floorplan bins, stands, vehicles)

Waste flow registration and tracking of the whole collection process

Minimization of waste contamination

Improved circularity of the location & clean working area

Higher availability of bins

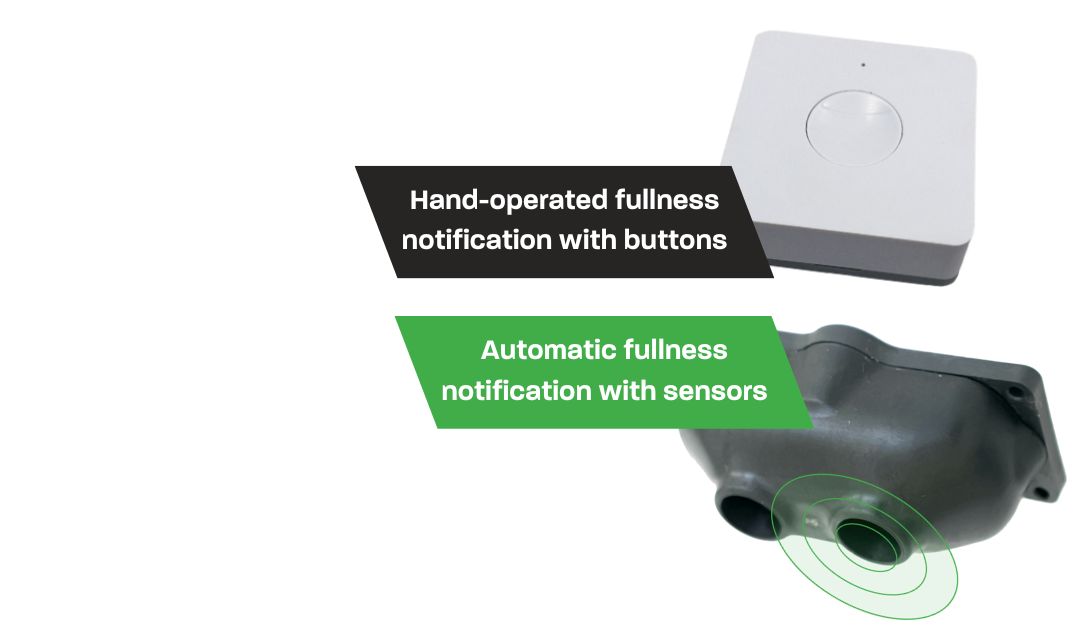

Fullness notification

Smart Button allows assigned personnel to indicate that the bin is full. Upon pressing, it sends notifications to the Sensoneo Platform. Smart Sensors feed Sensoneo Platform with live measurements on bin fullness several times a day. Both Button and Sensor can be placed on bins and containers of various types and sizes and send notification from both indoor and outdoor locations.

Smart Button is a simple and cost-efficient tool for hand-operated fullness notification. Smart Sensor is a reliable and effortless tool for automatic fullness notification.

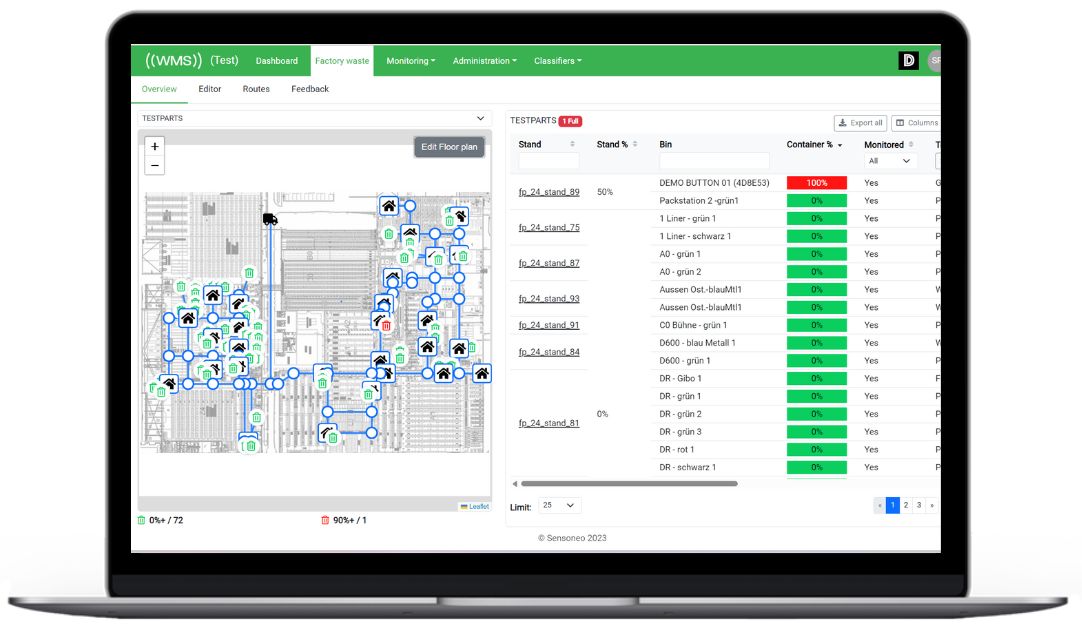

Waste Management Software Platform

The Factory Waste Management Operator immediately sees all the full bins in Dashboard and Route Planning Engine automatically recalculates the routes to accommodate the new full bin. Both Dashboard and Route Planning Engine are part of Smart Waste Management System, a powerful, cloud-based platform designed by Sensoneo. The waste management software platform offers comprehensive control over waste collection operations through remote management. It efficiently adapts to diverse rules and variables, enabling the accommodation of various scenarios. You can create a detailed database of all the bins including waste types, capacities, bin locations, and bin pickup points. Dashboard consolidates all the data from Smart Buttons, Smart Sensors and Mobile Collection App. By recalculating routes in real-time, particularly to address “full bin” notifications, the solution optimizes collection efficiency and responsiveness.

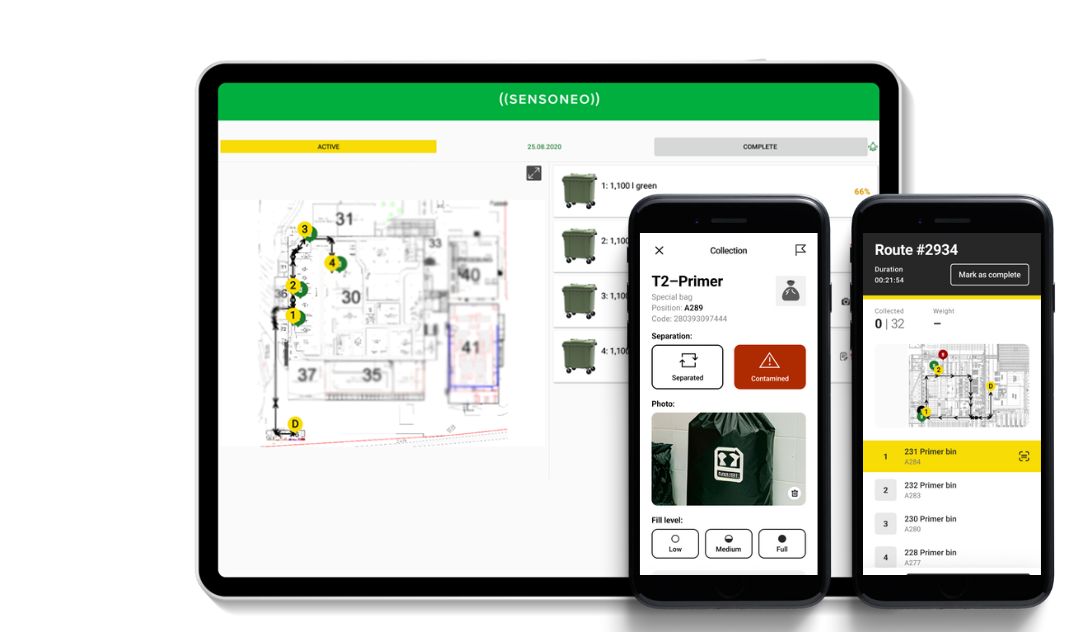

Mobile Collection App

Mobile Collection App revolutionizes waste management in factories by streamlining essential tasks. We designed the Dashboard in Smart Waste Management System for Operators and Collection App for Drivers/Collectors. Collection App helps drivers navigate the premises and identify bins for collection and transportation. It simplifies waste collection through a convenient To-do List, while Floorplan Navigation and QR code-based Bin/Stand Identification enhances operational efficiency. The app further ensures service verification and enables prompt contamination feedback, promoting effective waste management practices and accountability. Collection App sends all the data to the Sensoneo Platform and Operator has remote control.

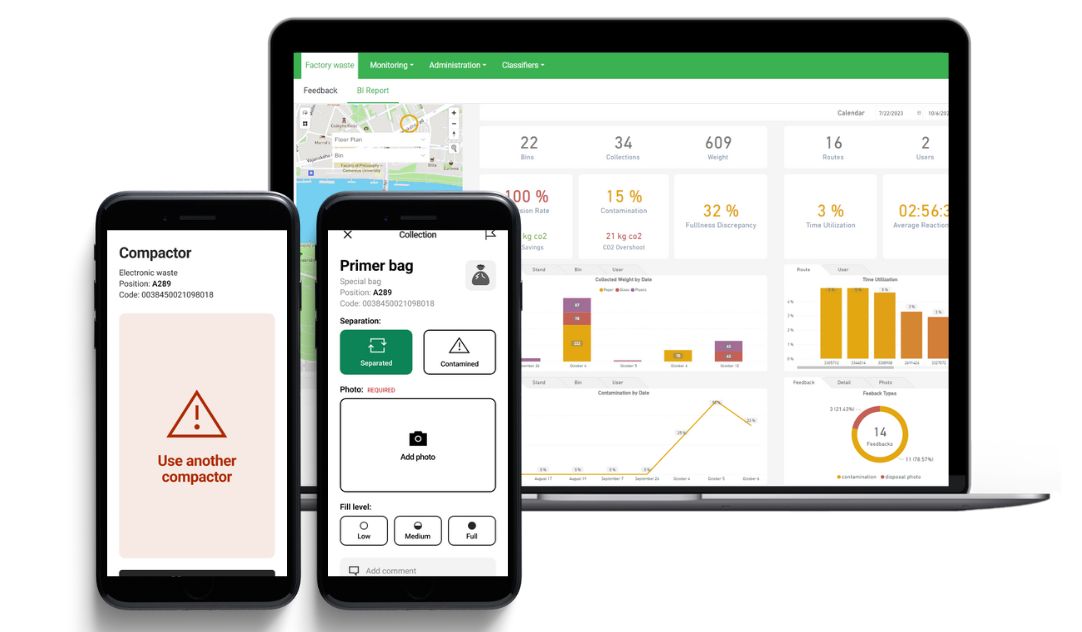

Insights for optimization

Our data reports offer valuable insights for waste management in factories by providing weight data for the supervision of internal/external waste collectors, as well as ESG reporting. They facilitate a comprehensive understanding of waste production and collection frequency, empowering data-driven decisions to enhance sustainability KPIs, such as Waste Diversion Rate. These reports play a pivotal role in optimizing waste management strategies and promoting a more environmentally conscious operational approach. We are happy to source our data to fully customizable dashboards in Smart Analytics (Qlik platform) or send tailored e-mail reports to help you run a more efficient operation and report easily to management.

Reach out to discover all functionalities of Factory Waste Management

Leave your contact details and we will reach out to you. Your contact information will not be used for any other purpose.