From 7 to 4 FTEs: Smart Waste Efficiency in Fulfillment Center

85 207€

Yearly Cost Savings on FTEs per facility

35,754kg

CO2 Savings per facility

99.82%

Waste Diversion Rate per facility

271

Digitalised bins

Achieving sustainability at fulfillment facilities with smart waste solutions

Project and customer description

The Smart Waste Management Project was initiated at European fulfillment center (to maintain confidentiality under our NDA, our client’s name will not be disclosed), a logistics hub well-known for its role in supporting supply chain operations for major enterprises. Facility is a key part of fulfillment network, which processes a significant volume of orders daily and requires efficient operations to maintain service quality.

Sensoneo provides innovative tools to improve waste collection efficiency, track environmental performance, and enable data-driven decisions. This partnership reflects our client’s broader commitment to sustainability and operational excellence.

The waste management system handles:

- 271 bins/containers across 16 areas of the facility

- 6 standard waste streams, including cardboard, plastics, and general waste

- 20 product-specific waste streams originating from customer and vendor returns

Challenge

- Inefficient Waste Collection: The traditional waste collection processes lacked real-time tracking and optimization, leading to inefficiencies in labor and resources.

- Limited Data Control: Waste data was controlled by external contractors, leaving fufillment center without critical insights into waste production and contamination issues.

- Environmental Concerns: High contamination rates and limited waste separation reduced waste diversion rates, impacting sustainability goals.

- Scaling Issues: A need for a scalable waste management system that could be implemented across other fulfillment centers.

Solution

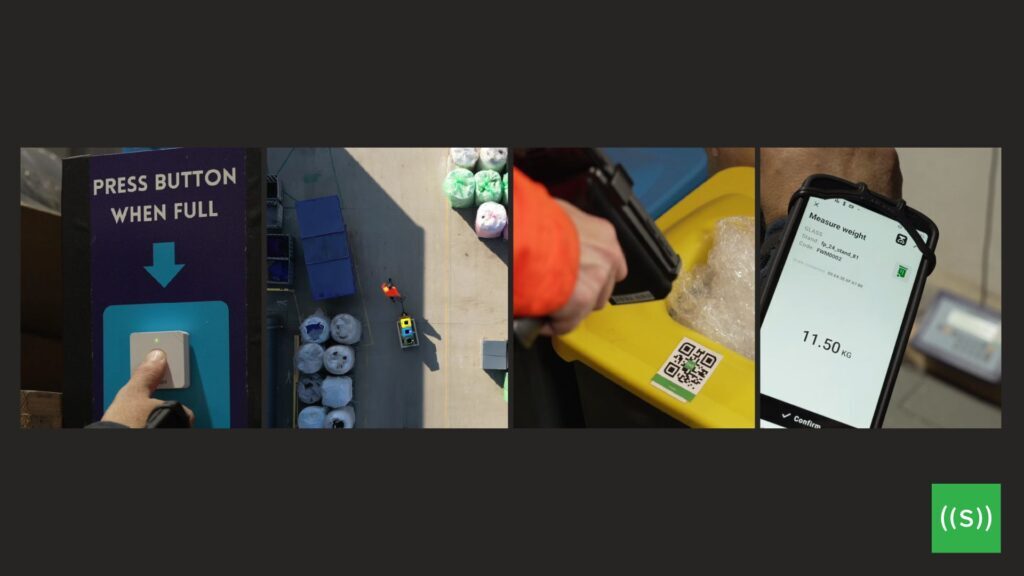

IoT and Software Integration

- IoT Buttons and Gateways: Enabled real-time monitoring of bin fullness and contamination

- Mobile and Web Applications: Provided tools for waste collection planning, tracking, and reporting

- Bluetooth Scales: Measured bin weights accurately for automated reporting

Infrastructure Setup

- 271 bins equipped with IoT buttons across 16 areas and 72 PODs

- Predefined collection routes optimized for efficiency

Data and Reporting

- The system collected and visualized data, including waste volumes, contamination rates, and collection frequencies

Impact

Efficiency Gains

- Reduced labor requirements from 7 to 4 Full-Time Equivalents (FTEs), resulting in significant cost savings

- Yearly cost saving on personnel expenditures: 85 207€

- Streamlined waste collection processes, reducing route times to an average of 6 minutes and 10 seconds

Environmental Benefits

- Achieved a 99.82% Waste Diversion Rate (WDR) and reduced contamination to just 1%

- Realized 35,754 kg of CO2 savings over the pilot period (June–August 2024)

Enhanced Data Control

- Fulfillment center gained full control over waste data, previously managed by external contractors

85 207€

Yearly Cost Savings on FTEs per facility

Key achievements

- Reduced workforce requirements

- Significant yearly cost savings

- High waste diversion rate

- Lower CO₂ emissions

- Scalable model for other facilities

Future outlook

- Implement contamination monitoring and improved tracking

- Scale the solution using a standardized implementation template

- Extend the project to other fulfillment centers of our client for similar efficiency gains

Smart Waste Newsletter

Get monthly updates from our company and the world of waste!