Take-Back System Enhances WEEE Collection Efficiency

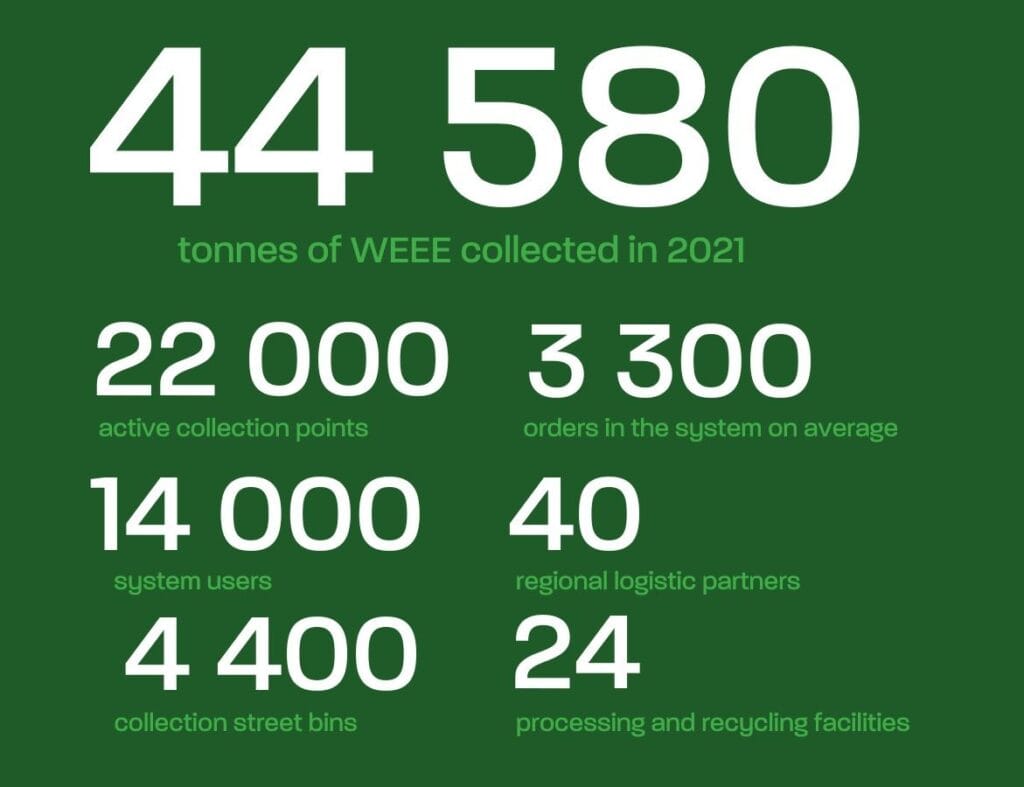

22.000

Collection points

14.400

System users

40

Logistic facilities

24

Processing facilities

Interview with Sarka Kohakova, Logistics Manager at ASEKOL CZ

What is Asekol and what do you do?

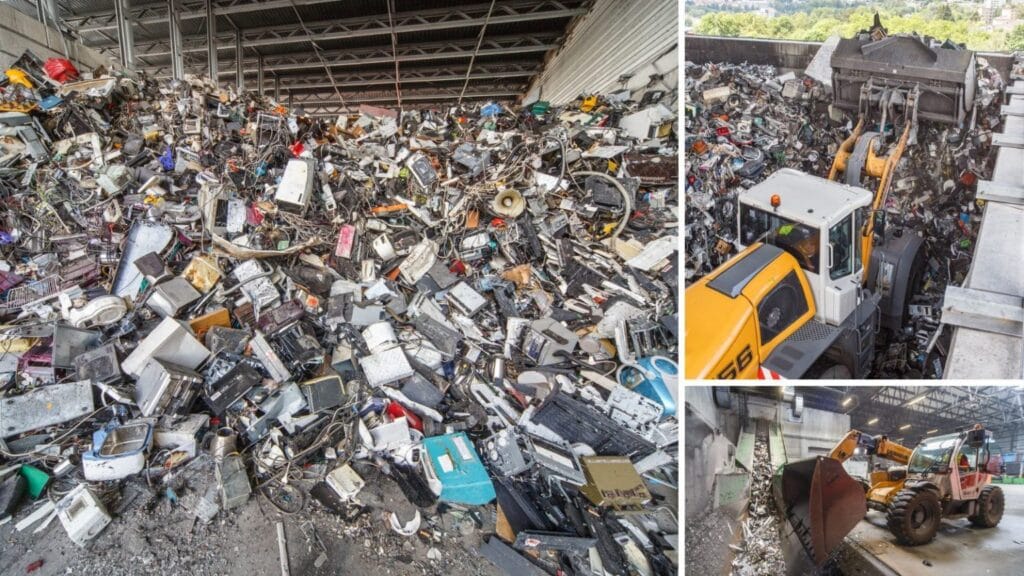

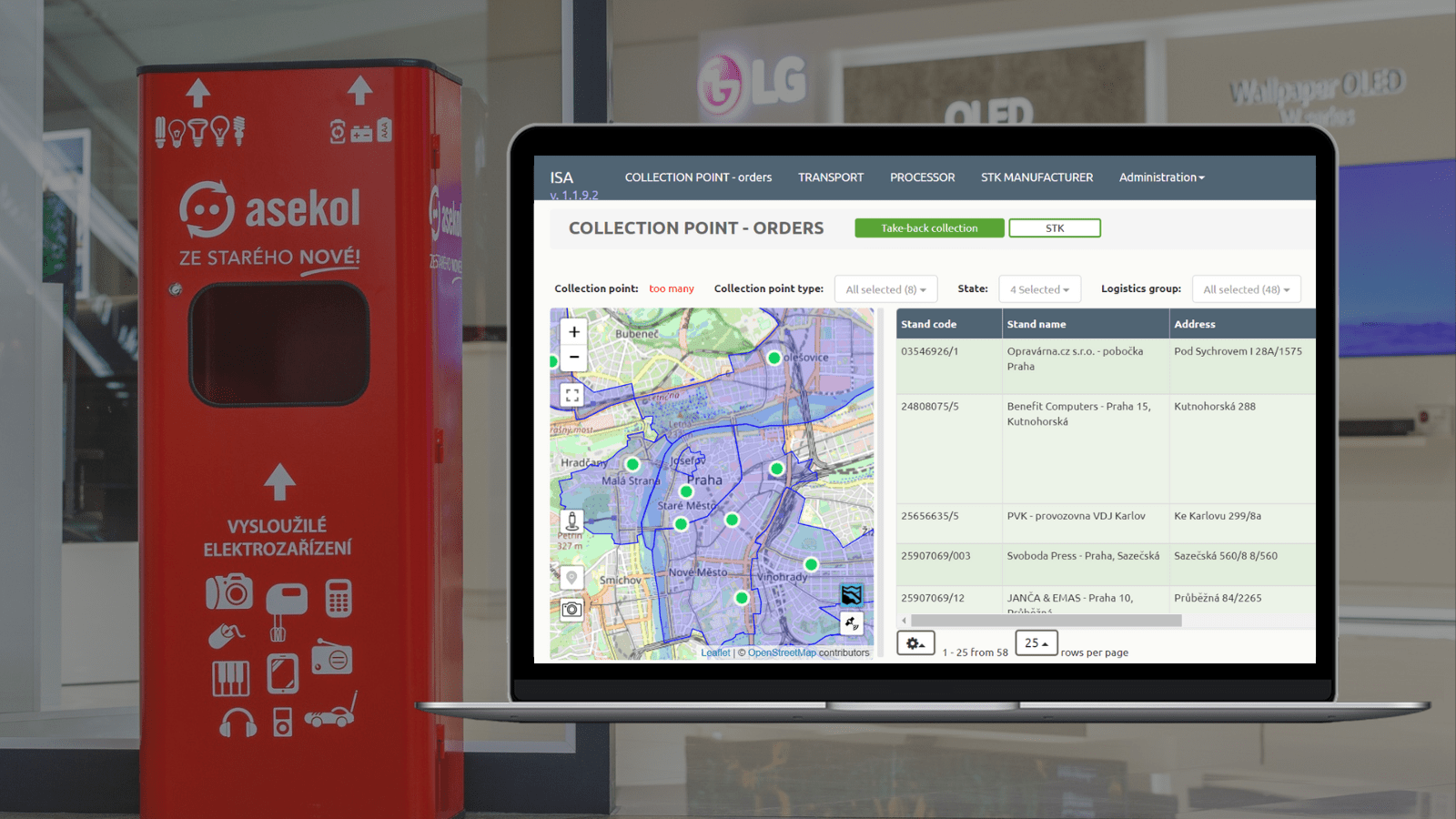

Asekol is a nationwide system for electronic waste collection. We deal with the collection, transportation, and recycling of used and discontinued electronic devices. Both manufacturers and distributors utilize our services and we collaborate with municipalities, sellers, service points, chain stores, but also garbage collectors, and e-waste processors. Scale-wise, Asekol is the most significant player in space in the Czech Republic. Asekol has its containers located at most collection points. These containers allow the collection points to consolidate the collected electronic devices. Some of these containers are static and intended only for the collection of electronic devices. Others are mobile and serve to transport the collected electronic devices. Our collection network is one of the most complex in the country.

What do your partners value the most in you?

Our strong suit is the efficiency of the entire process, timely order processing, and online support for customers. We are partnered up with dozens of transport companies that ensure the organization of the collections throughout the entire Czech Republic. Within the country, we cover 14 collection areas, which is quite a large area, and that is what makes us unique.

What are the most important tasks you complete?

Every stakeholder that collaborates with us seeks to reach their goals and therefore views our services as a means of accomplishing them. From the transport company’s point of view, it’s the timely collections they care about the most, so there are no delays in processing orders for collection points. The processors, on the other hand, value the proper handling of the received material, its utilization, and accurate reporting of the process. Our most significant task, however, is to fulfill our obligation to the law, which is to collect at least 65% of e-waste from products introduced to the market in the last 3 years. In 2021, the company collected a total of 44,580 tons of electrical equipment.

What exactly is the scale of your operations?

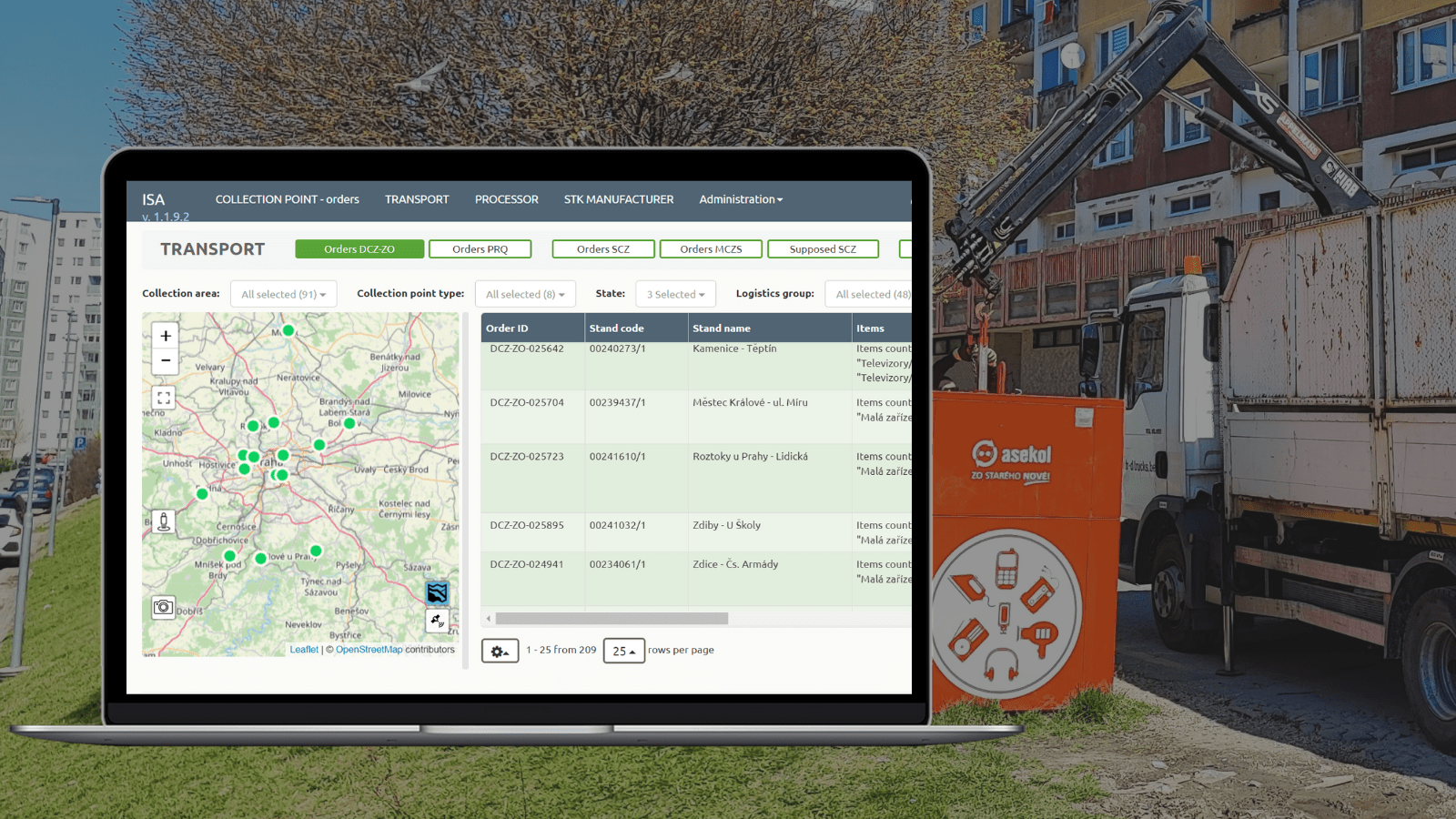

To have our system function on the scale that we work with, we need to work with data in real-time, making it our strong suit. The most excellent dynamics take place within the transport. Currently, we have around 22 000 collection points around the country – including containers and dozens of processing centers. Then, there are transport companies, which we divide into several categories. Part of them provides regional transport – which means e-waste collection from various collection points based on orders that these collection points put out. We also work with collection companies, which deal with our stationary containers using collection trucks with a hydraulic arm. Lastly, we have several transport companies for “on-demand requirements”, such as collections of large-volume containers.

Asekol has lately evolved its processes by utilizing a Take-Back solution. Why did you go this route?

Our goal was to digitalize our data and all processes to the maximum extent possible, since working with data in real-time and interconnecting our processes are our key operations. The correctness of the data is an absolute priority for us. The ISA tool, which is our internal name for the solution, works with data in real time online and is not only step forward for Asekol, but also helps us to be as efficient as possible in what we do.

What does Take-Back mean in your case?

It’s an IT system that works with data online. All our partners has access to the system via the web interface and insert their data there. The system includes an order module into which the collection representatives enter. Furthermore, a dispatch or transport module, which ensures the organization of logistics and transport, route planning, and order processing all the way from collection to delivery to the processing center. The transfer module is focused on monitoring material flow in and out of the transfer points. In reality, we have several of these transfer points, as it has a great impact on the efficiency of the entire transport. Consolidation of certain types of materials takes place at transfer points and accordingly they are subsequently sent to specific processors. Last but not least, the processing facility module is a part of the system, where we process orders from transport companies, and confirm material weight and the way it is been processed.

How did this system improve your operation?

Thanks to implementation of the Take-Back solution, we have changed the structure of our company – primarily by connecting smaller, separated departments. As an example, we can take the position of a dispatcher – a colleague who provides regional transport. The regional transport is tied to contractual unit prices and linked directly to price lists. It is provided on the basis of orders and runs more or less automatically. The transport companies receive the orders according to the collection area they are responsible for, and based on the completed orders, there is an automatic settlement. On the other hand, we also carry out the mentioned “on demand transports” which cannot be planned beforehand. They primarily concern large-volume containers and collection from transfer points. Thanks to the Take-Back system, these two types of transport work hand in hand under one integrated system.

“Automation of transport and logistics is definitely the most complex part of the entire solution. Once collection points create a transport order, the request is sent to all authorized transport companies for that type of material. Therefore, only transport companies who are authorized for that specific material can see the request.”

Jaroslav Galáš, Chief Product Officer at Sensoneo

“Subsequently, the tool behaves kind of like a “marketplace” – that means, the rule “first come, first take” is applied. After the order is approved, the system will automatically offer the carrier of the transport company recycling facilities where the material can be delivered. He chooses from the free dates offered, and the system then creates and plans a route that is approved by the carrier. The driver then sees this route in the application on the mobile phone, where he clicks on it and starts to fulfill it step-by-step. In the end, as part of the unloading, the driver ends the route, and the material is taken over by the recycling processor.”

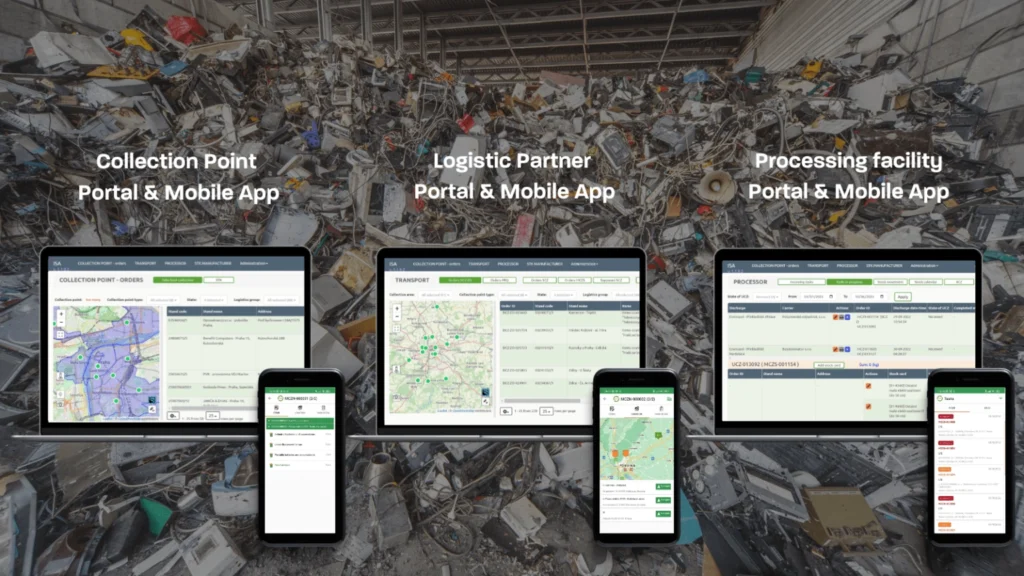

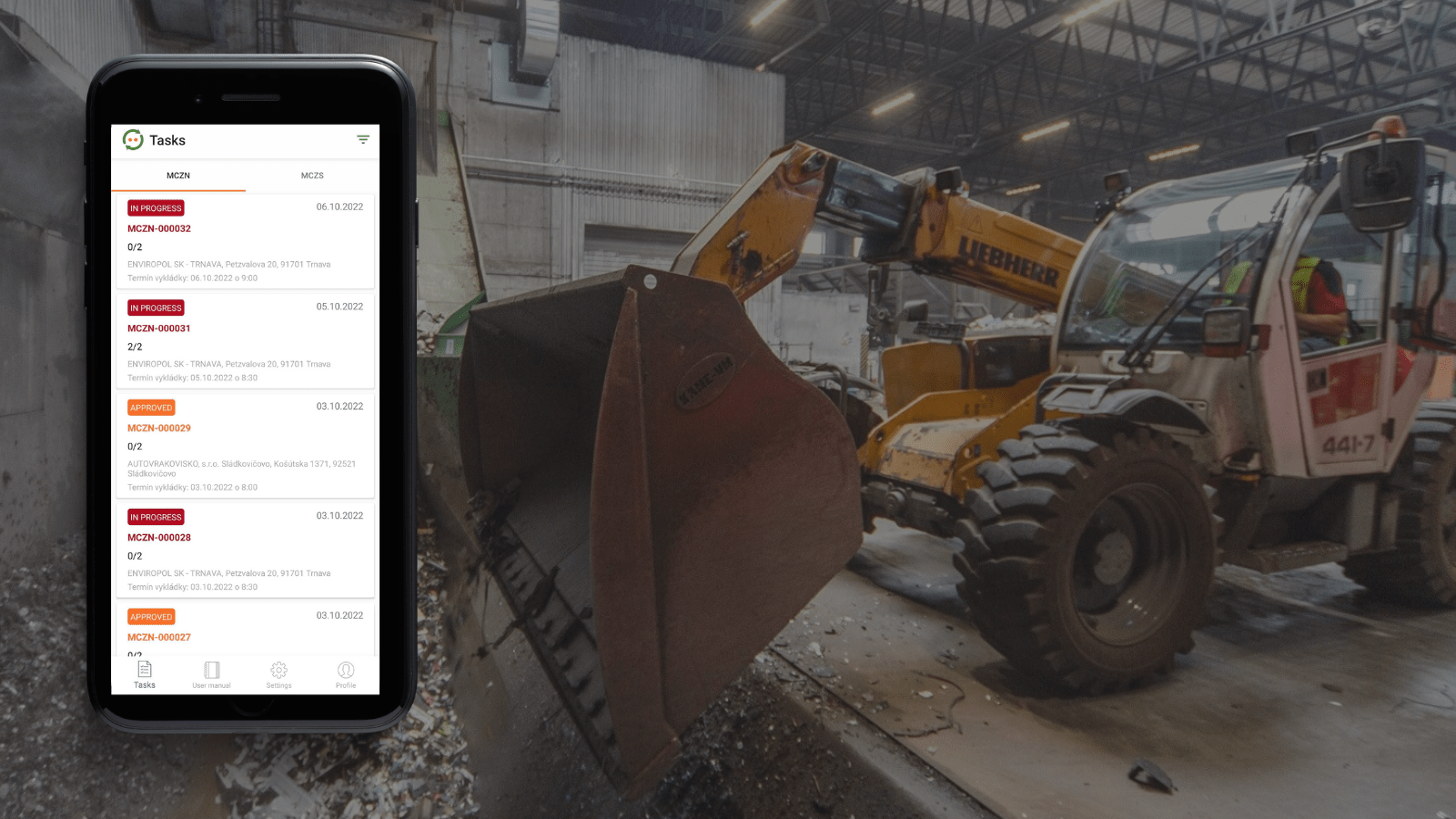

In total, we have prepared 3 mobile apps for the take-back system, which are very similar in design and structure, but each has different functionalities

1. Driver App

The most complex app is a driver app for transport companies. After order approval, the system will automatically offer the transport company places where the material can be delivered. The company chooses from the free dates offered, and the system then creates and plans a route that is approved by the transport company. The driver subsequently sees it in the app on the mobile phone, where he clicks on it and gradually implements it. In the end, as a part of unloading, the driver ends the route and the material is taken over by the processor. However, the app has several functionalities with added value not only for the transport companies but also for collection points and Asekol itself.

Several days can pass from the moment the order for the collection of e-waste enter the system until the moment when the driver comes to collect the order. This means that in a meantime, a new order can be created at that location, as a large amount of e-waste has again accumulated at the collection point. The system and the app allow the driver to agree and accept this new order in real-time when he is already physically at the given collection point, only in case he still has enough capacity in the car. This way, he can add this new order to the route that is currently in progress.

Another important function of the driver´s app is feedback regarding the damage or unavailability of the collection point. If, for example, the driver arrives at the collection point and the container is damaged or blocked or the driver did not have access to the premises – he has the option to report this in the app, and simultaneously add photos to the feedback.

The mobile app for drivers also enables the processing of orders for service and maintenance of containers. It is therefore not only about the orders that are used for the removal of e-waste, but also orders that are used for repairing containers, adding new containers, or removing containers in case the validity of the collection point has already expired or its contract has expired.

2. App for Warehouse Manager

Another application is for the warehouse manager, which is probably the simplest in terms of complexity because the warehouse manager only sorts the e-waste that arrived using the system that converts it into warehouse cards with waste codes (depending on whether it is, for example, batteries or televisions). Subsequently, he only weighs the waste and enters the weight into the system – at this moment, the most realistic and accurate information about the weight of the collected waste is created, since the collection point and the transport company only entered the estimated weight into the system. In the end, the warehouse manager just confirms the weights, and the process at the transfer point or processing center is finished.

3. App for Collection Points

Collection points also have a mobile app – creating an order for e-waste collection does not have to be done only via a desktop and web application, but it can also be done via a mobile app if it suits the collection point better.

“I see great value in both us and our stakeholders working under a shared system. It’s a great leap forward and I already see we have chosen well.”

Sarka Kohakova Logistics Manager at ASEKOL CZ

So then, your employees’ work gets simplified and less tedious?

Absolutely. Thanks to the apps that come with the system, we are able to get all of the data right as things happen, accurately and in real-time. For example, the transport companies put information about the fullness of the stationary containers into the app, as well as intel about collection or delivery, or any other updates from terrain that we might need. Without this data, it was difficult for us to get this information or it never arrived. Today, we have this data immediately.

As for you personally, which part of the solution do you see as the most significant?

Bin asset management is a highly complex task, which includes a very extensive work agenda and is connected to a very high amount of finance. We talk about thousands of containers that we use not only for collection but also for transport and logistics. We need to know not only their current location, but also to record requests for moving, removing or installing containers. This is a very big and significant part of our assets that we need to have under control. We plan to connect the Asset module to another module called “Administration of damage incidents”. Our regional representatives who work in the field will enter into the system damages and other incidents.

Selected success stories

Smart Waste Newsletter

Get monthly updates from our company and the world of waste!