Understanding the impact of industrial waste

Every day, industries around the world produce tons of waste, much of which ends up polluting our environment. The true impact of this industrial waste goes far beyond what we can see, affecting ecosystems, human health, and economies. Let’s dive into the hidden consequences of industrial waste and explore the urgent need for eco-friendly industrial practices.

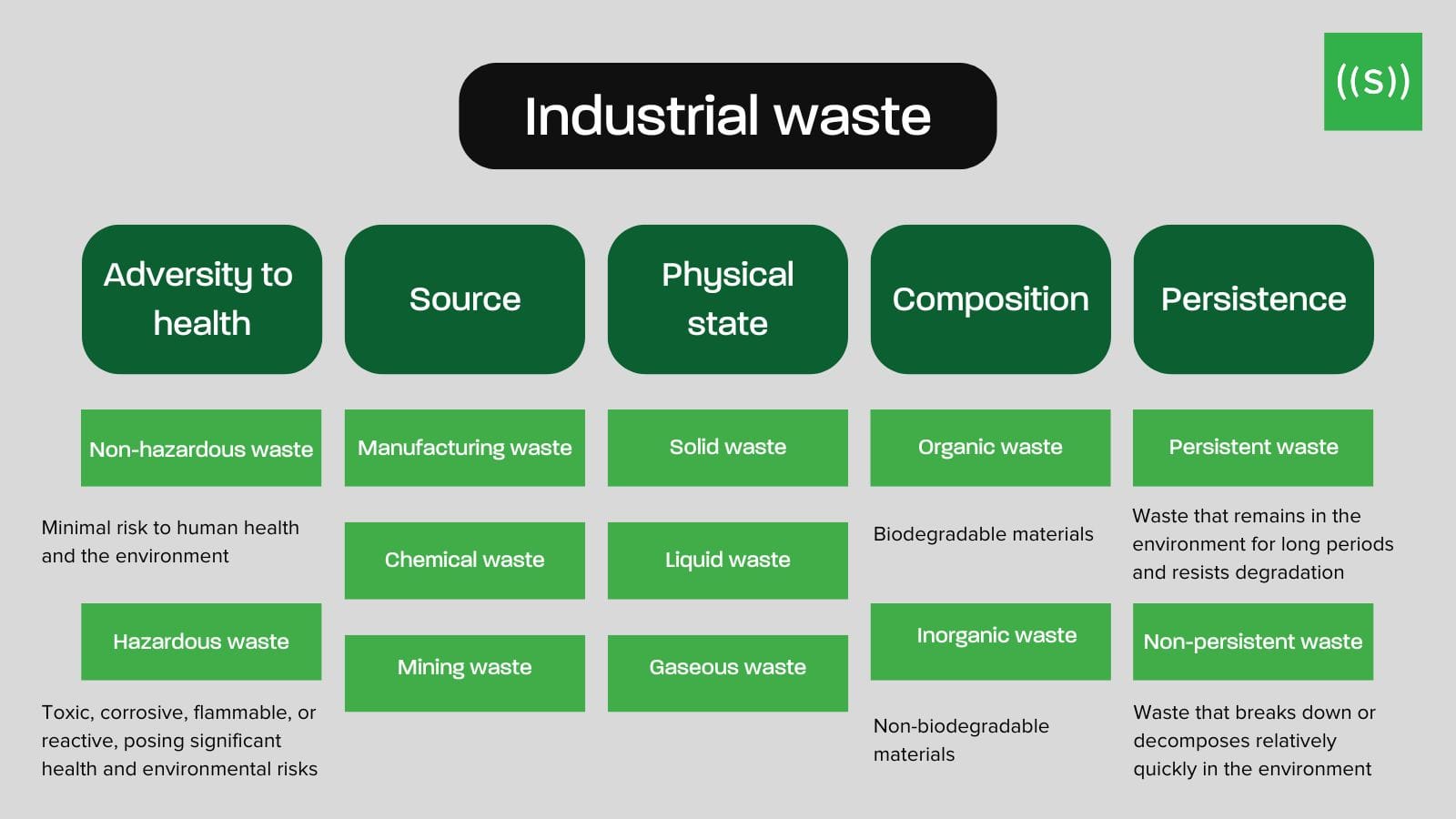

Industrial waste applies to material that is unwanted or residual produced by industrial activities. It differs according to various categories:

When it comes to adversity to health, the key difference between hazardous and non-hazardous waste is a significant threat to public health and the environment. Hazardous type of waste is typically generated from industrial, manufacturing, and medical processes and requires special handling, treatment, and disposal to mitigate its toxic risks. Regulations often dictate the specific methods for managing hazardous waste, including treatment, storage, and disposal protocols.

Non-hazardous waste, on the other hand, does not pose a significant threat to human health or the environment. It’s generated from everyday activities and can usually be disposed of in standard landfills or recycling facilities. Yet, we shouldn’t take non-hazardous waste lightly. Proper management, such as recycling and composting, is still important to minimize environmental impact.

Another important category is persistence. Persistent waste refers to materials that do not break down easily or quickly in the environment. These substances can remain in the ecosystem for many years, potentially causing long-term harm to wildlife and humans. Persistent waste is often associated with pollutants that accumulate and magnify through food chains, leading to serious ecological and health issues.

Non-persistent waste consists of materials that break down relatively quickly and do not pose long-term risks to the environment. These substances decompose through natural processes, returning to the ecosystem without causing significant harm.

Understanding where waste comes from is basic and important knowledge. Starting from chemical waste, let’s see how they differ. Chemical waste is any unwanted or residual material containing chemicals that pose a potential risk to human health or the environment. This type of waste is generated from various sources such as industrial processes, laboratories, agriculture, households, and healthcare facilities. It includes toxic, flammable, corrosive, and reactive substances, requiring careful handling, storage, treatment, and disposal to prevent environmental contamination and health hazards. Proper management and adherence to regulatory guidelines are essential to mitigate the risks associated with chemical waste.

Mining waste consists of the residual materials left after the extraction and processing of minerals and ores. This waste includes overburden (soil and rock removed to access mineral deposits), tailings (residues from ore processing), and slag (byproducts of metal smelting). Generated in large quantities, mining waste can pose environmental and health risks due to the presence of heavy metals, chemicals, and other pollutants. Proper management, including containment, treatment, and reclamation, is crucial to minimize its impact on ecosystems and human health, ensuring sustainable mining practices and regulatory compliance.

One of the biggest contributors to industrial waste is manufacturing waste. This waste does not add value to the final product and is essentially leftover or excess material generated during the manufacturing process. It has a negative impact on the environment in several ways:

Resource Depletion

The extraction of raw materials such as metals, wood, and fossil fuels for manufacturing depletes our natural resources. This unsustainable practice often results in severe consequences, including deforestation, habitat destruction, and water pollution.

Pollution

Manufacturing processes are significant contributors to environmental pollution. The release of chemicals and the burning of fossil fuels during production can emit harmful toxins into the air and water. Moreover, improper disposal of hazardous waste can lead to soil contamination, which poses long-term risks to both human health and the environment.

Energy Consumption

The energy demands of manufacturing are substantial. The processes involved in extracting, transporting, and processing raw materials, along with powering machinery, require vast amounts of energy. This energy consumption is primarily sourced from fossil fuels, leading to increased greenhouse gas emissions and exacerbating climate change.

Landfills

Manufacturing waste that isn’t recycled or properly managed often ends up in landfills. These landfills occupy valuable land and can leach harmful chemicals into the soil and groundwater. As organic waste decomposes in landfills, it generates methane, a greenhouse gas far more potent than carbon dioxide.

Overall, if not managed properly industrial waste can cause fatal consequences. It can lead to environmental contamination, polluting air, water, and soil, and harming ecosystems and wildlife. Water pollution from untreated industrial discharge affects aquatic life and drinking water sources, while air pollution from industrial emissions contributes to smog, acid rain, and respiratory problems. Soil degradation from improper waste disposal reduces agricultural productivity and harms plant and animal life. Health risks for workers and nearby communities include respiratory issues, skin diseases, and long-term illnesses like cancer. Additionally, industrial activities contribute to climate change through greenhouse gas emissions, exacerbating extreme weather events and biodiversity loss.

Now, understanding the gravity of the situation, let’s look at some waste treatment technological solutions:

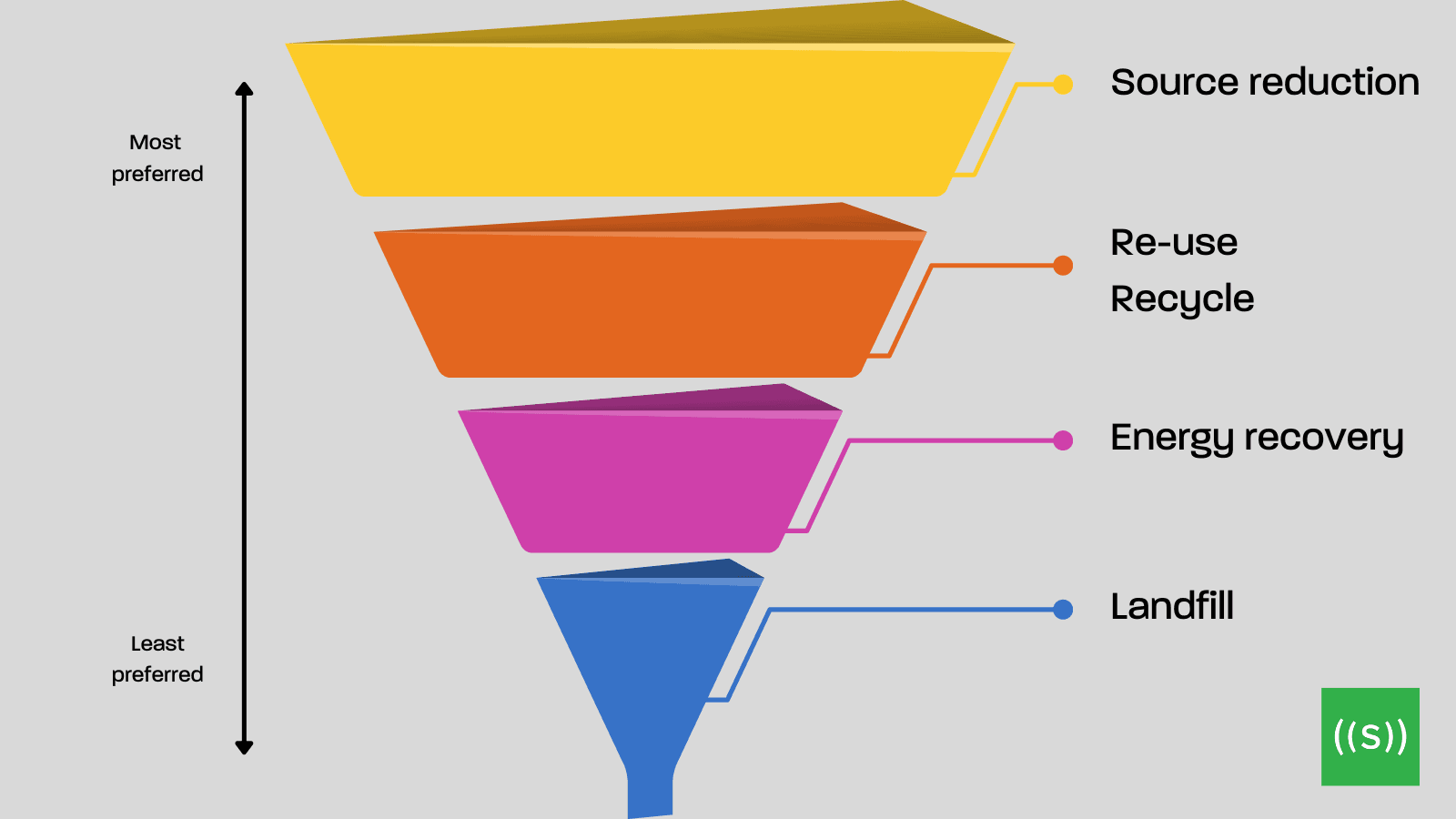

Reduce Waste at the Source

This means designing products and processes that inherently generate less waste.

- Computer-Aided Design (CAD) software: allows for more precise product design, minimizing material use.

- 3D printing: creates objects layer-by-layer, reducing scrap material compared to traditional methods.

- Lean manufacturing techniques: optimize production flow, minimizing inefficiencies and excess materials.

Repurpose or Recycle Waste

Once the waste is generated, technologies can help divert it from landfills:

- Recycling equipment: processes scrap metal, plastics, or other materials back into usable raw materials.

- Repurposing techniques: finding new uses for leftover materials, like using fabric scraps for smaller products.

- Advanced sorting systems: automate the separation of different waste streams for efficient recycling. Thanks to this feature, you can access data like the waste diversion rate, enabling you to make the right decisions.

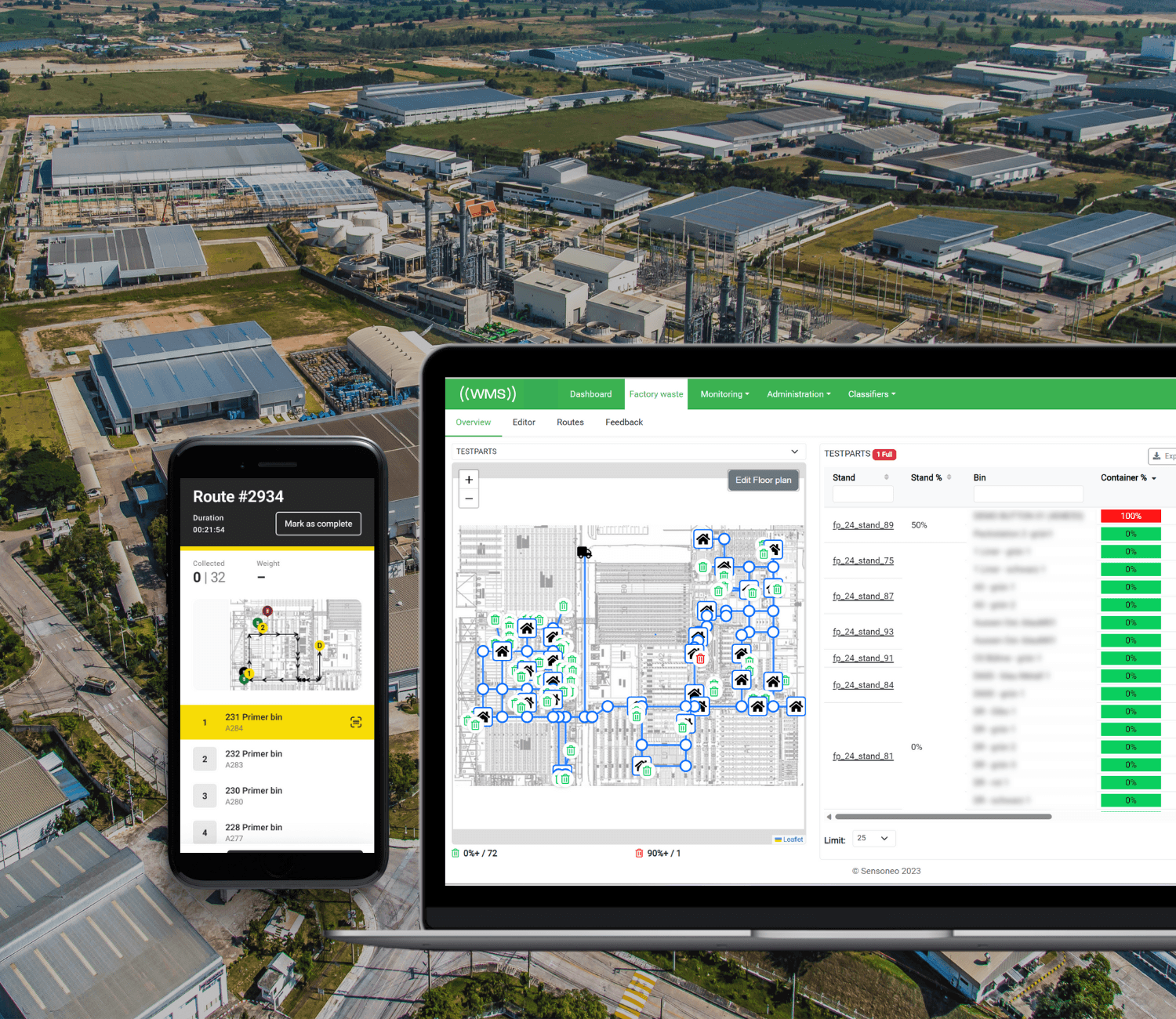

Eco-friendly industrial practices are crucial for managing waste in manufacturing industries. Having everything said, here are the three key factors that can help your industry manage manufacturing waste like a pro. Sensoneo has extensive experience in optimizing waste management across various industrial use cases worldwide.

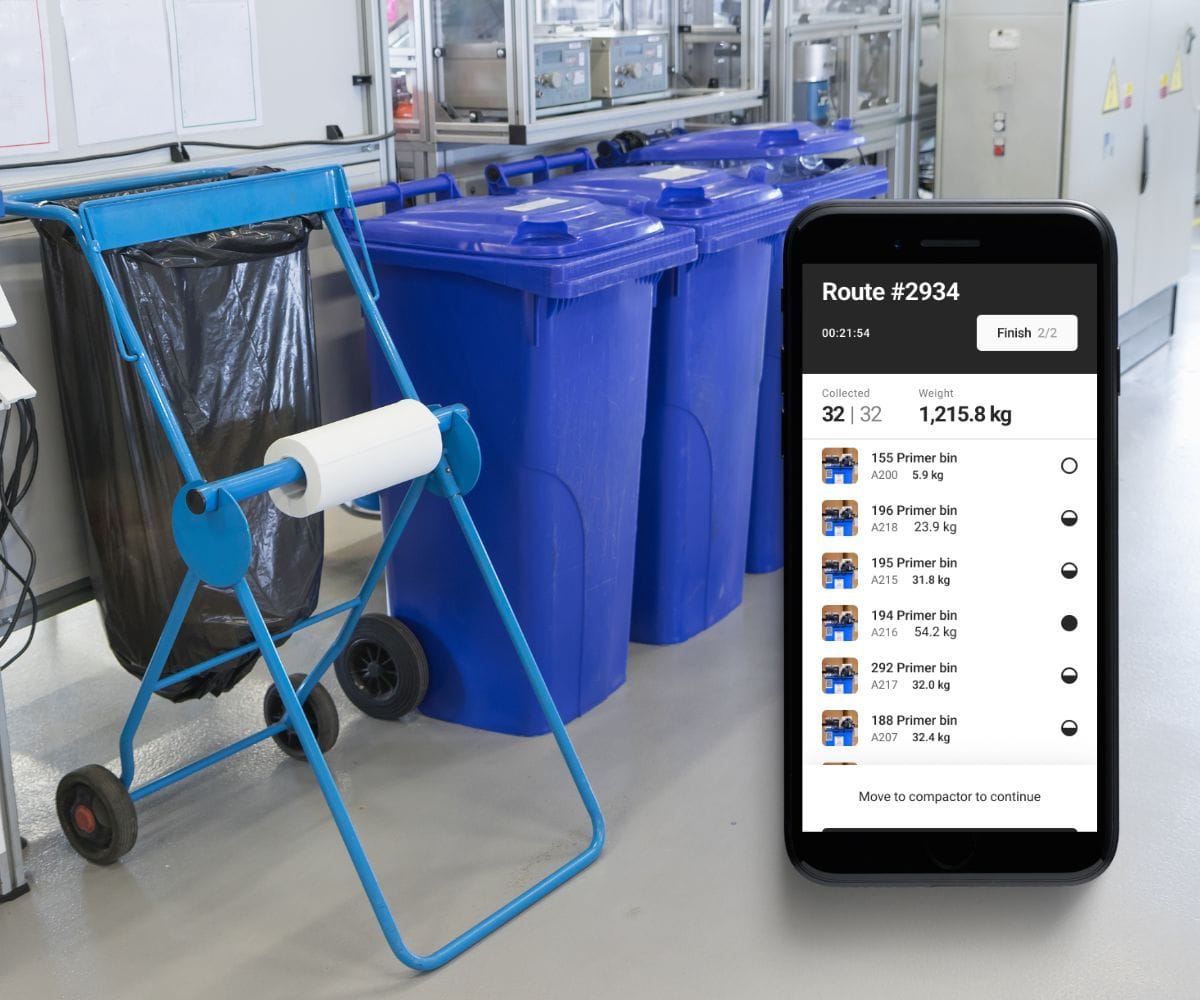

Minimizing Collection Resources

This involves optimizing collection processes to reduce environmental impact. Key strategies include route optimization for efficient travel, right-sizing collection vehicles to match waste volumes, and promoting recycling programs to reduce overall waste collection needs.

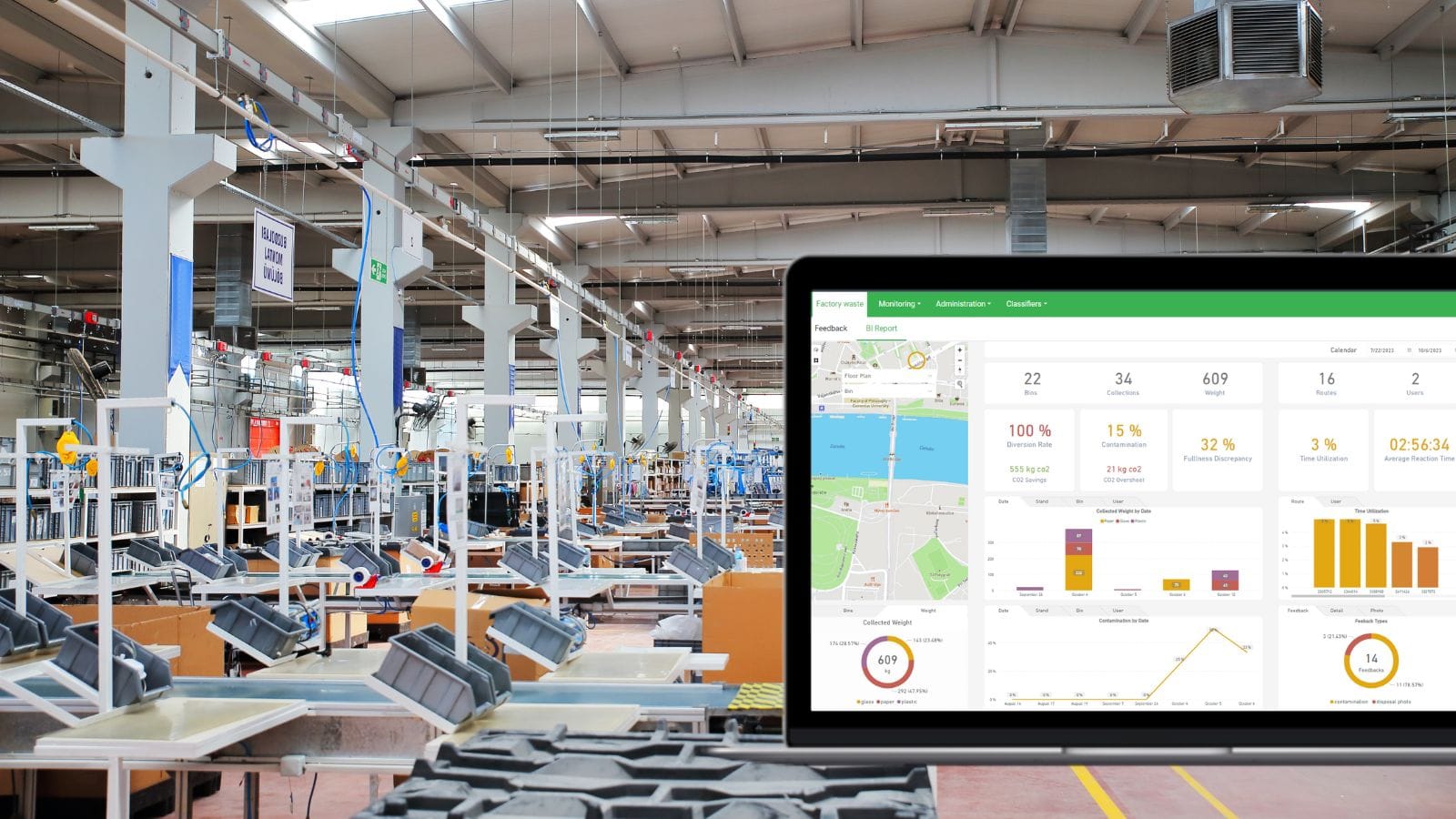

Sustainability KPIs and Waste Diversion

Key performance indicators (KPIs) track progress towards sustainability goals. Waste diversion rate, a core KPI, measures the percentage of waste diverted from landfills through recycling, composting, or reuse. Higher diversion rates indicate a more sustainable system.

Complex Data for ESG Reporting and Optimization

Collecting comprehensive waste management data allows for Environmental, Social, and Governance (ESG) reporting, demonstrating commitment to sustainability. By analyzing this complex data, optimization strategies can be further refined. For example, advanced route planning software can optimize collection routes based on historical data and real-time factors.

Sources: researchgate.net, sinergilestari.id , katanamrp.com

Latest waste library articles

How to prevent used cooking oil theft

Waste Collection

ESG Reporting made clear: Compliance & best practices

Factory Waste Management

6 Best Circular Economy projects and initiatives worldwide

Environment

How can the Deposit Refund System look like?

Smart Waste Newsletter

Get monthly updates from our company and the world of waste!