Industrial waste management trends to watch in 2025

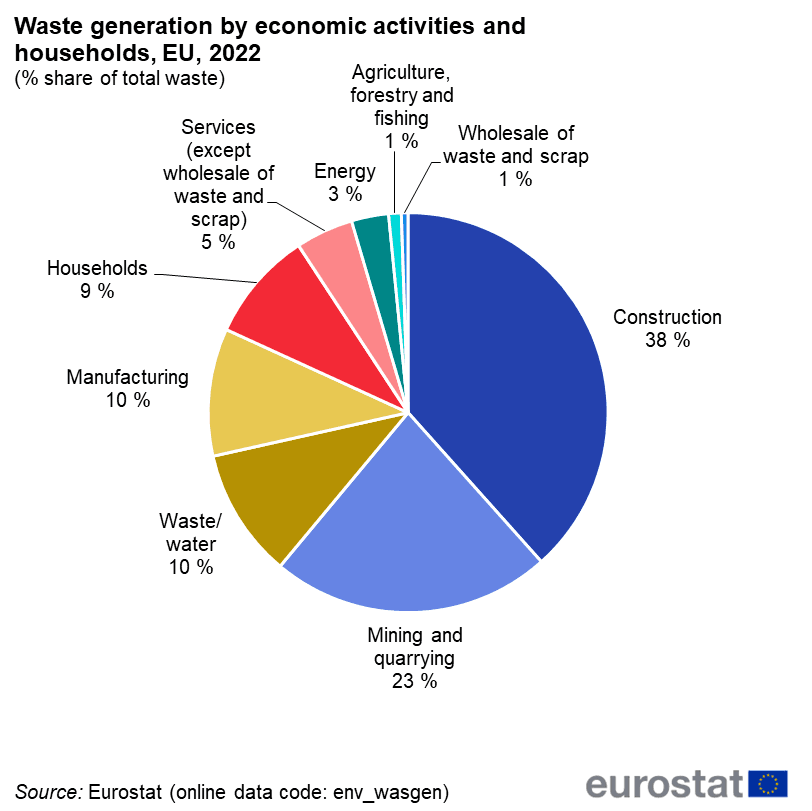

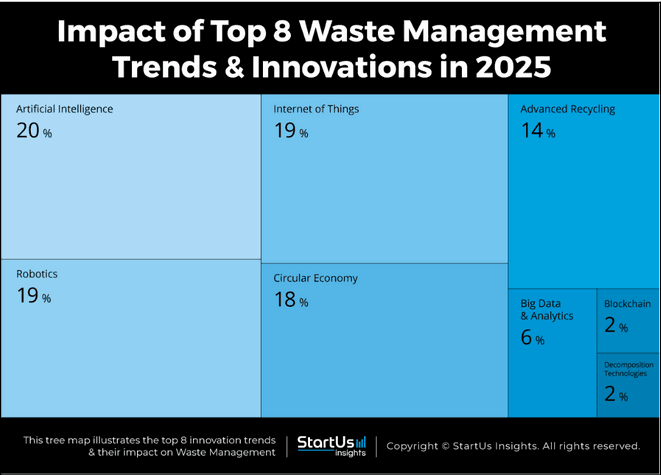

The year 2025 will be full of innovations and changes, with new restrictions and stricter policies in waste management on the rise. Many companies are adopting smart waste management systems to handle waste more easily and efficiently. It is important mainly for manufacturing companies to implement smart solutions, as in the EU, industries, and mining generate nine times more waste than households, and manufacturing alone produces more waste than all households combined. Moreover, global waste generation is predicted to increase by 70% by 2050, according to a report by the WorldBank.

When we think of waste, we often picture household trash, and while it is a significant issue, it represents only a fraction of the problem. Every year, approximately 2 billion tons of municipal waste are generated globally, with the U.S. and EU among the highest per capita contributors. Managing this waste remains a major challenge for cities worldwide. However, municipal waste is just the tip of the iceberg. In the EU, industries and mining generate nine times more waste than households, and manufacturing alone produces more waste than all households combined. Addressing industrial waste is crucial for achieving a truly sustainable waste management system.

This situation is alarming and calls for urgent action and innovation. Let’s get inspired by new trends and practices in 2025 and face this situation responsibly and together.

1. Artificial Intelligence

Artificial Intelligence (AI) is a powerful tool in industrial waste management as it can learn complex practices, if you invest time in training it. It is well known, managing waste is a challenging task, requiring strength and time. However, using AI can save both time and energy.

Today, AI is primarily used in industrial waste management as a tool for sorting, including:

AI-powered image recognition

This task, when handled by humans, was prone to human error. Now, as it uses artificial intelligence and machine learning to analyze visual data—identifying objects, patterns, and even text—the quality of sorting has improved. Key technologies that support this process include object detection, image labeling, and optical character recognition (OCR).

Sorting recyclable vs. non-recyclable materials

Sometimes, recyclable and non-recyclable materials end up mixed together—like when a glass bottle accidentally gets tossed in with plastic recyclables. Using advanced machine learning models, these systems can quickly identify different materials, such as plastics, metals, glass, organic waste, and even hazardous items like batteries or electronics. By analyzing visual data, AI can distinguish between recyclable and non-recyclable materials, reducing contamination in recycling processes.

Detecting hazardous or contaminated waste

The last thing we want while handling waste is to contaminate it. Thanks to AI-powered image recognition systems, waste management facilities can automatically scan and detect hazardous materials within waste streams. These systems can be trained to recognize specific visual features of hazardous waste, such as chemical labels, unusual shapes, or materials that require special handling.

One of the successful integrations of AI into waste management systems is Greyparrot. Greyparrot specializes in AI-powered waste analytics to enhance recycling efficiency and reduce environmental impact. Their primary product, the Greyparrot Analyzer, is an AI waste analytics platform that uses camera systems to capture real-time images of waste flows and generate insights through intuitive dashboards. This system has the ability to identify characteristics like mass, brand, emissions potential, and more across over 89 categories of material. The data collected provides valuable insights into waste composition, helping facilities optimize sorting operations, increase recycling rates, and reduce contamination. Additionally, Greyparrot offers Greyparrot Sync, an integration system that connects their AI to third-party machinery and software (Robot, PLC, Baler, NIR), making it even more useful.

2. Robotics

Even though using robots might sound like science fiction, with modern technology, it has become quite common. Robots deliver food in restaurants, assist in various industries, and even manage waste! The previously mentioned AI often acts as the “brain,” controlling robotic arms or tools to carry out learned waste management practices. Robotic arms work faster and lift heavier objects as compared to humans. Here are some of the most interesting robots used in industrial waste management:

AMP Robotics (USA):

Their robotic sorting system processes materials up to four times faster than manual methods. AMP Vision captures images and sends them to AI, which identifies each item based on material type, shape, color, polymer, and even brand. The AI then directs the robot to sort the waste with precision!

ZenRobotics Recycler (Finland):

Call them robots,

call them pickers,

call them recyclers.

What they do is spotless waste sorting work

They have developed specialized robotic arms for waste sorting: Heavy Picker for bulky waste and Fast Picker for lighter materials. Their AI system, ZenBrain, helps sort construction and demolition waste, including wood, metal, and stone.

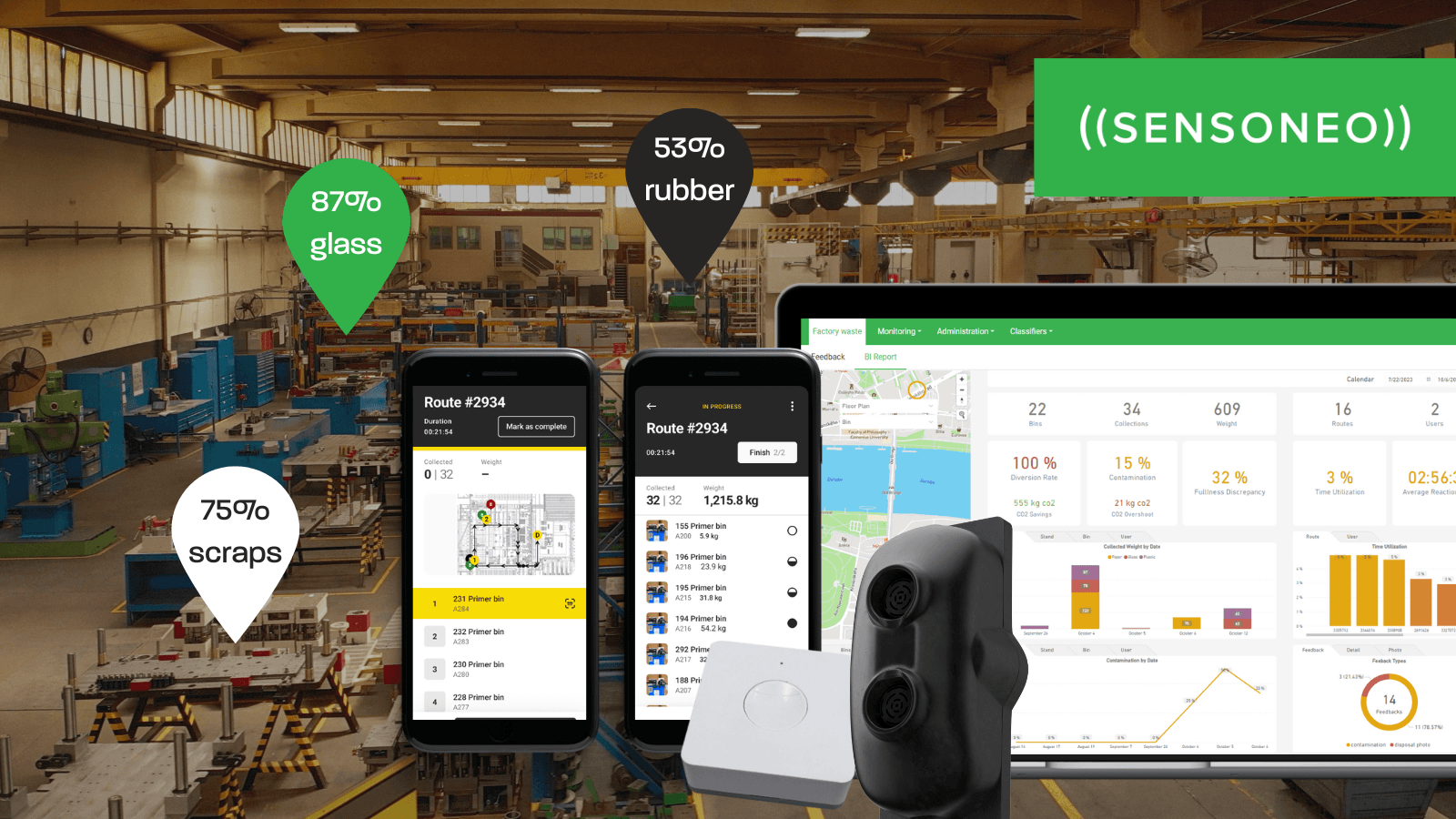

3. Internet of Things

The Internet of Things (IoT) refers to a network of connected devices that communicate and share data with each other. In waste management, IoT is used to monitor waste levels, optimize collection routes, and track waste types, improving efficiency and reducing costs. Bins equipped with this advanced technology are known as Smart Bins.

Smart Bins using IoT

IoT-enabled smart bins utilize advanced ultrasonic sensors to revolutionize waste collection and management. These sensors monitor fill levels in real-time, detecting when bins are nearing capacity and sending automated alerts to waste management operators. By leveraging data analytics, smart bins optimize collection routes, reducing unnecessary pickups and lowering fuel consumption. Additionally, these systems can detect temperature changes, identify hazardous waste, and prevent overflow, contributing to cleaner and more efficient urban environments.

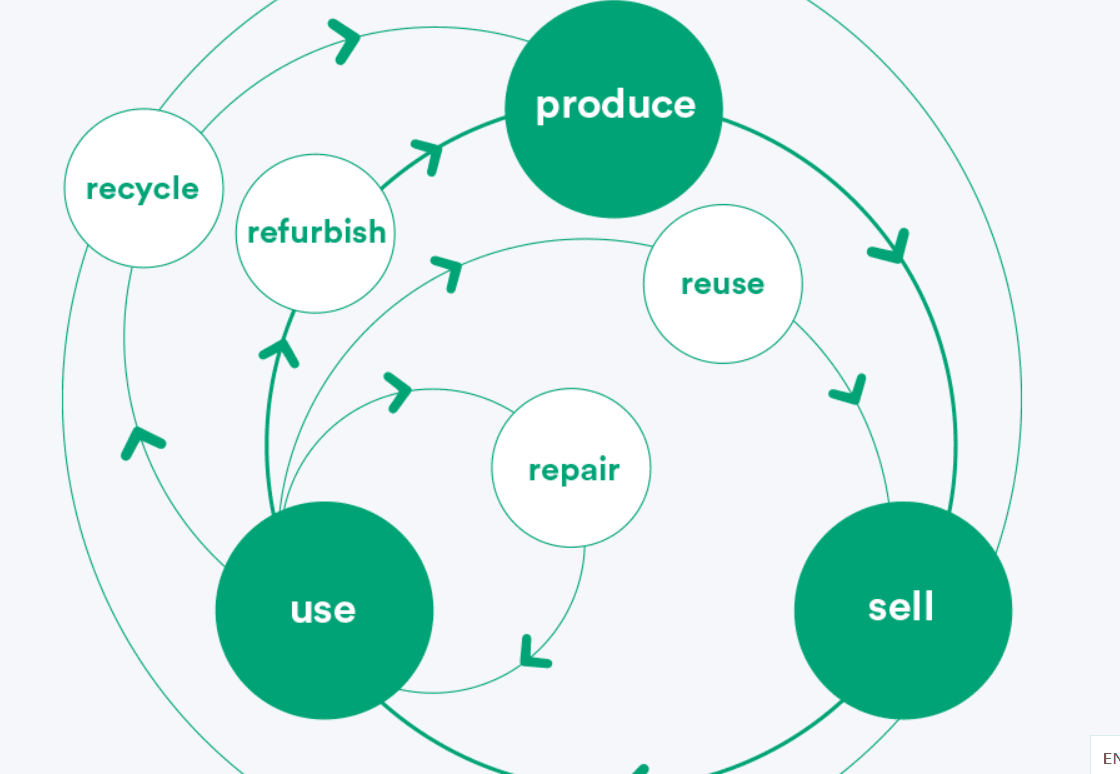

4. Circular economy

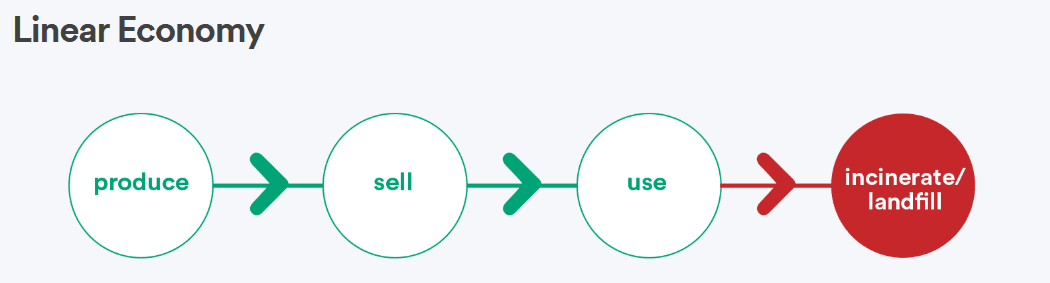

As the name suggests, a circular economy is an economic system based on a closed-loop approach. But what exactly does this mean ? Especially in waste management? It can be compared to a linear economy, where waste often ends up in landfills, serving no further purpose and harming the environment. In contrast, a circular economy focuses on reusing, recycling, and reintegrating waste back into the economic cycle, creating a continuous loop that minimizes waste and maximizes resource efficiency.

Circular economy is following 4 principles called 4R:

Reduce: Preventing waste generation from the outset by focusing on sustainable design and production practices that enhance product longevity.

Reuse: Repurposing products or materials to extend their lifespan, keeping them in circulation within the economy for as long as possible.

Recycle: Processing discarded items into raw materials to create new products. Although widely promoted, recycling is considered a last resort in the hierarchy of circular economy practices.

Recover: Extracting materials or energy from items that can no longer be reused or recycled, such as composting organic waste or converting waste into energy.

5. Advanced Recycling

Advanced recycling in waste management is gaining significant attention due to exciting new experiments and innovative methods of converting waste into reusable materials. Below is an interesting list of innovative technologies that break down waste material:

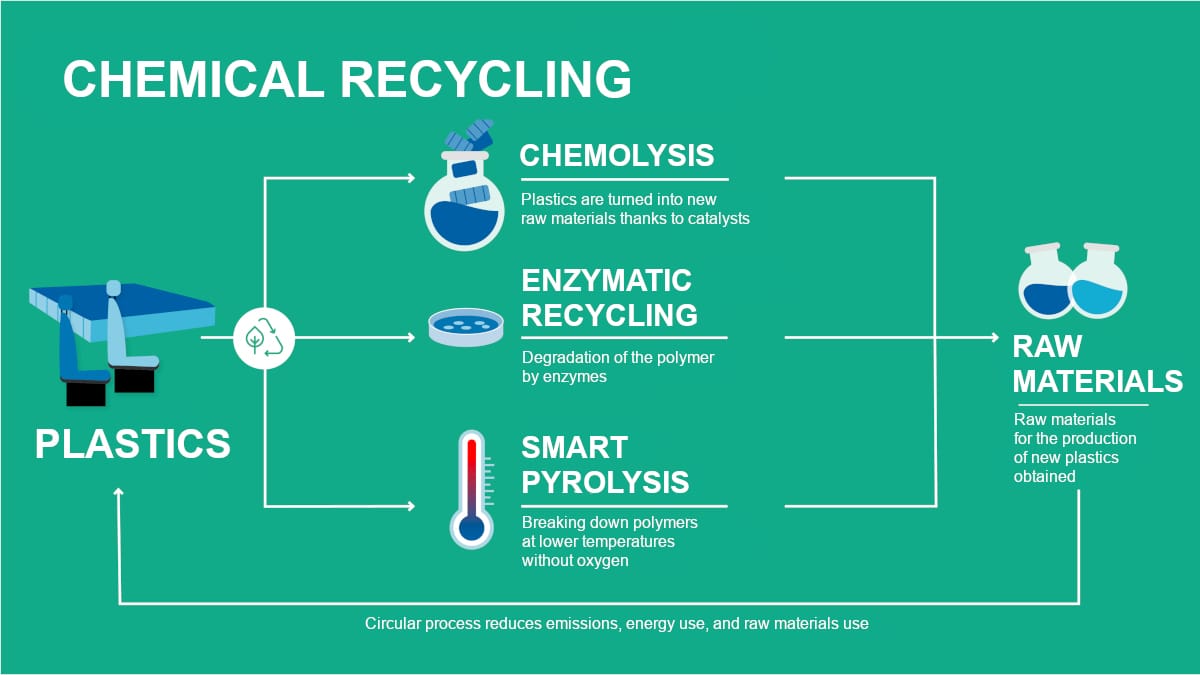

Chemical Recycling:

- Chemolysis: In chemolysis, polymers break down into monomers or raw materials using solvents, catalysts, heat, and sometimes pressure. Pyrolysis decomposes polymers into smaller building blocks under inert conditions at 500–800°C.

- Enzyme-Based Recycling: Researchers are developing enzymes that can break down plastics, especially PET, into their original monomers. This could allow for the recycling of plastics back into their virgin form, reducing waste and promoting a circular economy.

- Pyrolysis: A method that uses heat in the absence of oxygen to break down plastics and other waste materials into valuable products like oil, gas, and char. This can be used to recycle plastics that are otherwise difficult to process.

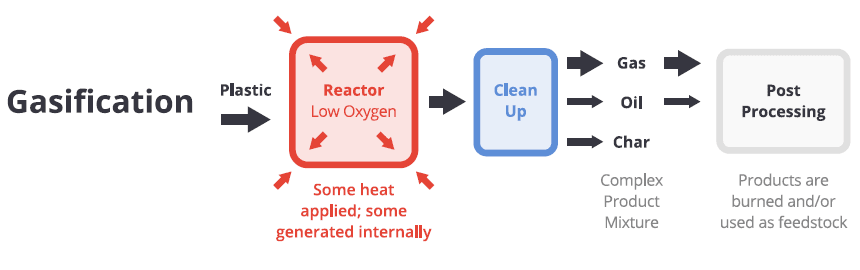

Gasification:

Gasification is a process that converts waste into syngas (a mixture of hydrogen and carbon monoxide) through high-temperature chemical reactions, without combustion. This syngas can be used for energy, fuels, or chemicals. The method is more efficient and eco-friendly than incineration, producing fewer harmful emissions and allowing for better waste recycling.

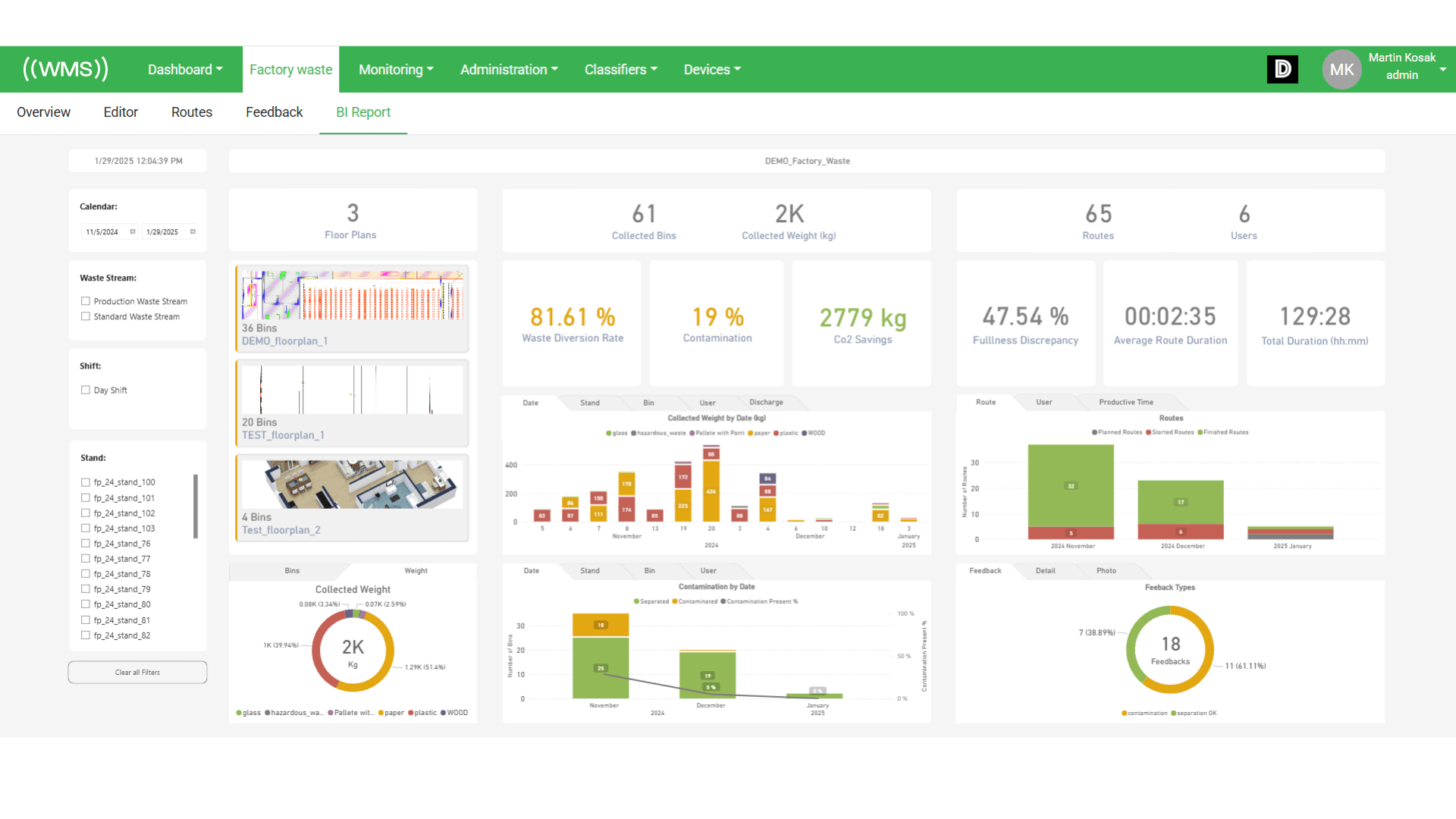

6. Big Data Analytics

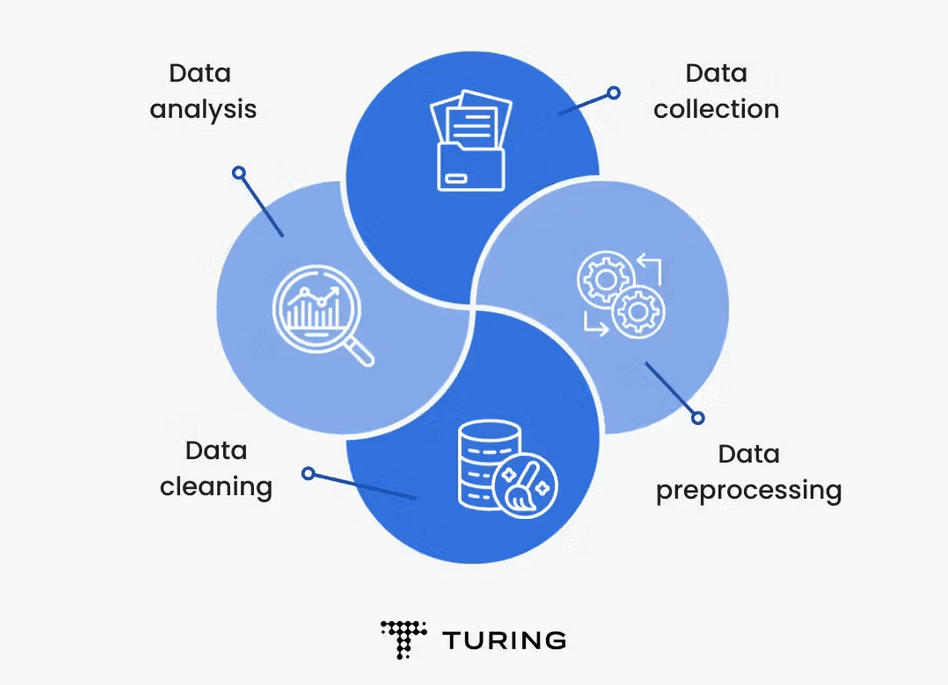

“Big data analytics involves massive amounts of data in various formats, including structured, semi-structured and unstructured data. The complexity of this data requires more sophisticated analysis techniques. Big data analytics employs advanced techniques like machine learning and data mining to extract information from complex data sets.” according toIBM.

When considering industrial waste management, you might wonder how big data analytics can play a role. Here are some key advantages of integrating big data into waste management processes:

- Quality of Data: Big Data ensures that waste-related data is accurate, timely, and consistent, supporting better decision-making and efficient operations.

- Statistics on Vehicle Use: Big Data tracks vehicle usage, helping optimize fleet management, reduce fuel consumption, and improve maintenance schedules.

- Statistics on Bin Fill-Level: Real-time data on bin fill levels allows for optimized collection schedules, preventing overflow and improving efficiency.

- Statistics on Collection Costs: Big Data analyzes collection costs, helping identify areas for savings in fuel, labor, and vehicle maintenance.

- Statistics on Bin Distribution: Big Data helps optimize bin placement by analyzing waste generation patterns and user behavior, improving accessibility and recycling rates.

- Statistics on Route Efficiency: Big Data optimizes collection routes, reducing fuel consumption, travel time, and emissions while ensuring timely pickups.

Sources: medium.com, bridgera.com

Latest waste library articles

From consumption to recycling: 7 stages of a beverage container

Deposit Return System

5 Biggest organized waste crimes worldwide

Environment

The role of big data in optimizing industrial waste management

Industrial Waste

Automated waste management helps factories reach ESG goals

Factory Waste Management

Smart Waste Newsletter

Get monthly updates from our company and the world of waste!