In today’s rapidly evolving industrial landscape, the need for sustainable waste management solutions has become more pressing than ever. As environmental concerns grow, companies are seeking innovative solutions to optimize their waste management processes, minimize their carbon footprint, and strive to meet ESG goals while maximizing efficiency and cost-effectiveness. Sensoneo’s Factory Waste Management solution emerges as a game-changer. Factory Waste Management solution combines IoT devices, Smart Waste Management System, a powerful software cloud-based platform, and a Collection App for Drivers, allowing any factory to obtain valuable information on the type, amount, and location of waste generated in the facility. In this article, we explore the key advantages of Sensoneo’s technology transforming the way factories manage their waste, making it more efficient, cost-effective, and environmentally responsible.

1. Automation of Waste Management

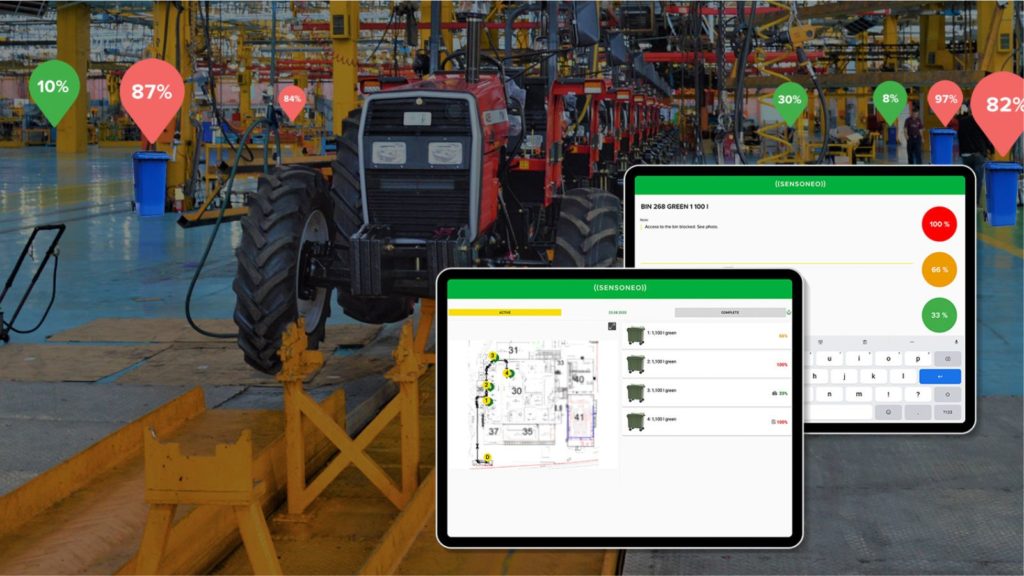

The cornerstone of Sensoneo’s waste management solution lies in its advanced automation capabilities. Traditional waste management systems often rely on manual processes, leading to inefficiencies, delays, and inaccuracies. Sensoneo’s cutting-edge technology uses IoT devices and smart sensors, enabling factories to monitor waste levels in real time. Automated alerts are triggered when bins reach capacity, streamlining waste collection and ensuring timely pick-ups, significantly reducing the risk of overflow and environmental hazards. Sensoneo’s Smart Waste Management system and collection app streamline the process, and optimize the collection, allowing drivers to efficiently navigate and collect waste on the floor plan dynamically.

2. Increasing the Efficiency of Waste Storage and Collection leads to lower expenses

By automating waste management processes, Sensoneo helps factories optimize waste storage and collection routines. Factories can save valuable resources, including time and manpower, by eliminating unnecessary trips to empty partially filled bins. The increased efficiency of waste collection also leads to reduced operational costs and improved overall profitability.

3. ESG Reporting

Sustainability has become a critical aspect of businesses across industries. Sensoneo’s waste management solution provides factories with valuable data and insights for their sustainability initiatives, which is also essential for ESG reporting. Precise and open waste data empowers companies to monitor their advancements, establish ambitious objectives, and efficiently convey their environmental footprint to stakeholders. With the help of Sensoneo’s solution, factories achieve significant CO2 savings in various areas, tackle contamination issues and promote higher recycling rates.

4. Supervising the External Waste Collector

Factories often rely on external waste collection services, leading to challenges in tracking and verifying the waste collection process. Sensoneo’s solution offers a transparent interface for supervising external waste collectors. Through waste weighing and real-time tracking within the application, factories gain access to comprehensive data and a clear overview of the precise amount of waste generated. This enables them to ensure they are billed only for the actual quantity of waste exported by the waste collector.

5. Overview and Map of the Bins

Sensoneo’s intuitive dashboard provides a comprehensive overview of all waste bins on the factory premises. This user-friendly interface allows factory managers to monitor waste levels, collection schedules, and any potential issues with specific bins at a glance. The interactive bin mapping feature ensures that the waste management process is streamlined and easily accessible for users.

6. Waste Flow Registration

Accurate data collection is crucial for effective waste management decisions. The application meticulously logs and tracks each and every action involving the bin, starting from the initial collection and binding, all the way through disposal into a larger compactor or skipper. Sensoneo’s Waste Flow Registration system precisely measures and records the amount and types of waste generated. Armed with this valuable data, factories can identify patterns, optimize processes, and even explore opportunities for waste-to-energy or waste-to-resource initiatives.

7. Minimizing Contamination of Waste

Contamination of waste streams is a significant challenge faced by factories. It not only hampers recycling efforts but also poses environmental risks. Using Sensoneo’s Factory Waste Management solution helps by detecting inappropriate waste disposal, allowing factories to intervene promptly and educate employees or waste generators about proper waste segregation.

8. Improve the Circularity of the Location

Embracing circular economy principles is essential for sustainable growth. Sensoneo’s Factory Waste Management solution brings more opportunities & encourages factories to adopt circularity by promoting responsible waste disposal, recycling, and resource recovery. By reducing waste sent to landfills and maximizing recycling rates, factories can close the loop and contribute to a more circular economy.

9. Higher Availability of the Bins

Overflowing bins or unavailable waste disposal options can lead to disruptions in the production and workflow of the factory. Sensoneo’s solution ensures that bins are promptly emptied when reaching capacity, maintaining a higher availability of waste disposal options for factory employees.

10. Clean Working Area

A cluttered and untidy workspace can hamper productivity and employee morale. Sensoneo’s waste management solution ensures that factories can maintain a clean working area by preventing overflowing bins and managing waste more efficiently. This, in turn, fosters a positive and healthy work environment.

Sensoneo’s Factory Waste Management solution stands at the forefront of innovation as the world embraces sustainability and environmental responsibility. By automating waste management processes, optimizing efficiency, and providing valuable data insights, Sensoneo empowers factories, facilities, or even fulfillment centers to meet ESG goals, reduce costs, and contribute to a cleaner, greener environment. With its focus on circular economy principles, waste flow registration, and contamination control, Sensoneo is leading the way toward a more sustainable industrial landscape. Factories that integrate Sensoneo’s solutions are enhancing their waste management capabilities and demonstrating their commitment to environmental stewardship and responsible corporate practices.